| |

TM 10-3930-653-14&P

2.

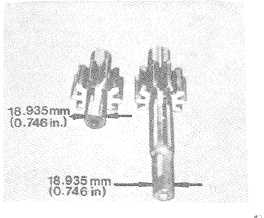

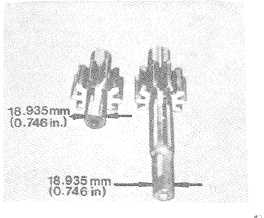

Check the drive and driven gear teeth for damage. If

(damaged, replace the drive and driven gears as a

set. Moreover, measure the outside diameter of

shaft, and if less than 18.935mri (0.746 inch),

replace the, .shaft

3.

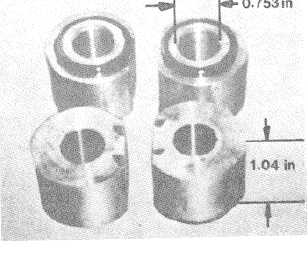

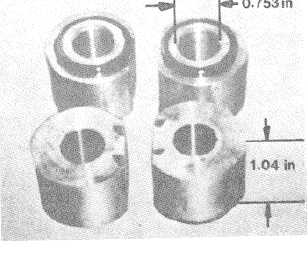

Measure the overall length of bushings. If not correct

replace the bushing and gear at the same time if

necessary. In addition, if the shaft-to-bushing

clearance is found to be more than 0.177mm

(0.006968 inch), replace the bushing and gear.

•

In the case where the drive gear or driven

gear is necessary to be replaced, replace

them as a set only.

•

The clearance between the bushing and gear

at the shaft should be within 0.005mm

(0.000197 inch). If either the bushing or gear is

defective, replace them' as a set only.

REASSEMBLY

Before reassembling, make sure that

all disassembled parts are clean.

1.

If the oil seal was removed from the pump body,

proceed as follows:

a.

Make sure there is no foreign matter or flaw

on the oil seal fitting part of the pump body.

b.

Using a press, install a new oil seal with the lip

inward.

2.

Apply a good quality mineral grease on new 0-rings

and install these O-ring on the two bushings marked

"C" on the end face. Then, install the two

bushings in the pump body at the same time with the

O-ring side toward the outside of the pump.

3. Wrap vinyl tape around the spline portion of the drive

gear and install in the pump body. Now, install the

driven gear. When the gears are reused, reinstall

them, aligning the matchmarks made during the

disassembly.

4-203

|