| |

TM 10-3930-653-14&P

Centrifugal advance mechanical parts

When cause of engine trouble is traced to centrigual

advance mechanical part. use distributor tester to check

its characteristics.

When nothing is wrong with its characteristics,

conceivable causes are faultiness or abnormal wear of

driving part or other part.

Do not disassemble it. In case of improper

characteristics, remove on-off switch part and check cam

assembly closely. governor weights. shaft and governor

springs, etc.

When centrifugal advance mechanical parts are

good, be sure to check advance characteristics with a

distributor tester.

4-7-7-3. DISASSEMBLY AND ASSEMBLY

(1) DISASSEMBLY

To disassemble, follow the procedure below.

(1) Take off cap and disconnect rotor head.

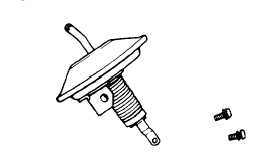

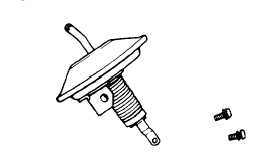

(2) Remove vacuum controller.

Fig. 4-210. Disassembling Vacuum Controller

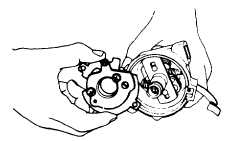

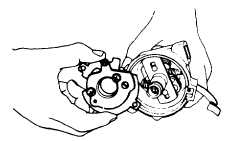

(3) Remove contact breaker.

Fig. 4-211. Removing Contact Set

(4) When contact breaker is disassembled, be careful

not to lose steel balls between breaker spring and

breaker plate.

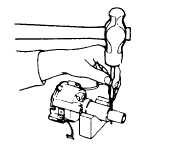

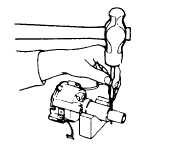

Fig. 4-212. Removing Contract Breaker

(5) Pull knock pin out and disconnect collar to remove

the entire rotating parts.

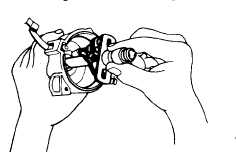

Fig. 4-213. Removing Knock Pin

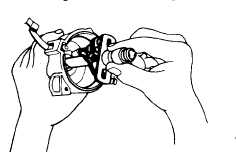

Fig. 4-214. Removing Rotation Parts

(6) When cam is to be removed, first remove set screw

since shaft head is fastened by the screw to hold cam

down. Put match mark across cam and shaft so that

original combination can be restored at assembly.

(7) When

governor

weights

and

springs

are

disconnected, be careful not to stretch or deform

governor springs.

After disassembling. apply grease to governor

weights.

4-117

|