| |

TM 10-3930-653-14&P

First turn out set screws I to 1.5 turns at contact arm

and primary lead wire connection just far enough to pull

out primary lead terminal.

Referring to Fig. 7-58 unscrew two contact set

screws and remove lead wire.

While holding contact arm with fingers, pull out

contact set toward you by raising it slightly. Contact point

and arm can then be removed together.

Install new contact point and arm assembly In

reverse sequence of removal. Coat cam heel and cam

shaft head with a light coating of grease.

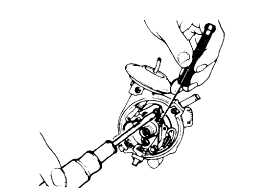

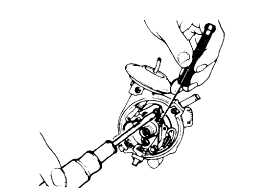

Fig. 4-208. Measuring Point Gap

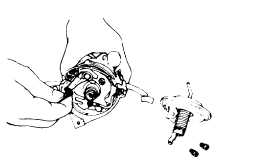

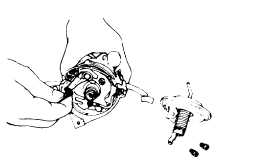

Fig. 4-209. Disassembling Contact

Arm and Contact Point

(3) CONDENSER

Satisfactory performance of ’condenser depends on

capacity and degree of insulation. requiring attention to

be sure that terminals are clean and set screws are tight.

Checking of condenser is made by a capacity tester.

This can also be made by a circuit tester with its range

set to high resistance reading. When needle of tester

swings *violently and then moves back to "infinite"

gradually. It Is an indication that the condenser is in good

condition.

If needle shows any steady reading or if it registers

zero. the likelihood is that the condenser is out of order.

calling for replacement.

(4) ADVANCE MECHANISM

D413-99

Start

rpm

625

Centrifugal

Intermediate

degree/rpm

-

Advance

Maximum

degree/rpm

15/1,550

performance

characteristics

Start

mmHg (inHg)

150 (5.91)

Vacumm

Intermediate

degree/-mmHg (-inHg)

8.5/300 (I 1.81)

Maximum

degree/-mmHg (-inHg)

11.25/390 (15.35)

Vacuum advance mechanism mechanical parts

If vacuum advance mechanism fails to operate

properly, check for the following Items and correct the

trouble as required.

(1) Check vacuum inlet for signs of leakage at its

connection. If necessary, retighten or replace with a new

one.

(2) Check vacuum diaphragm for air leak.

If leak is found, replace diaphragm with a new one.

(3) Inspect breaker plate for smooth movement.

If plate does not move smoothly, this condition could

be due to sticky steel balls or pivot. Apply grease to steel

balls or, if necessary, replace breaker plate as an

assembly.

4-116

|