| |

TM 10-3930-653-14&P

Test probe of a circuit tester

(-)

(+)

Conduction

terminal

(+) plate

0

(+) plate

terminal

-

terminal

(-) plate

-

(-) plate

terminal

0

(-) plate

(+) plate

0

(+) plate

(-) plate

-

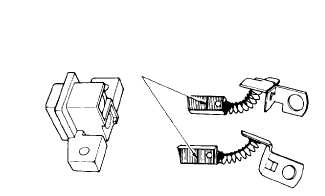

Fig. 4-190. Inspecting Diodes

(4) INSPECTION OF BRUSH

Check the movement of the brush and if movement

is unsmooth. check brush holder and clean it.

Check the brush for wear. If It is worn down to less

than the specified limit. replace brush assembly.

Check brush pig tail and, if found defective, replace.

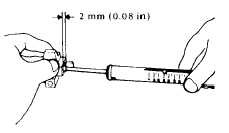

Fig. 4-191. Brush Wear Limit

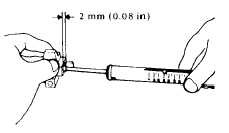

(5) SPRING PRESSURE TEST

With brush projected approximately 2 mm (0.08 in)

from brush holder, measure brush spring pressure by the

use of a spring balance. Normally, the rated pressure

of a new brush spring Is as follows.

Spring pressure:

0.33 to 0.44 kg

(0.73 to 0.97 lb)

Moreover, when brush is worn, pressure decreases

approximately 20 g (0.7 oz) per 1 mm (0.04 in) wear.

Fig. 4-192. Measuring Spring Pressure

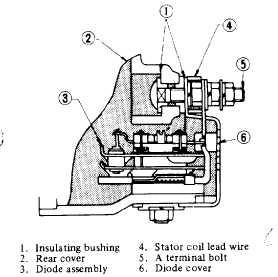

4-7-5-5. ASSEMBLY

Reassemble alternator in the reverse sequence of

disassembly noting following points.

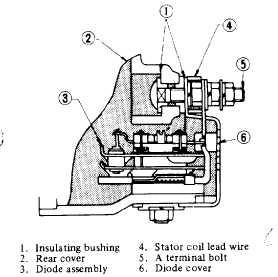

(1) When soldering each stator coil lead .ire to diode

assembly terminal, carry out the operation as fast as

possible.

(2) When installing diode in the "A" terminal. install

insulating bushing and insulating tube correctly.

Fig. 4-193. Diode and A Terminal

4-108

|