| |

TM 10-3930-653-14&P

when installed on engine. The starting motor should also

be subjected to a test when the cause of abnormal

operation is to be determined. A brief outline of test is

given below.

No-load test

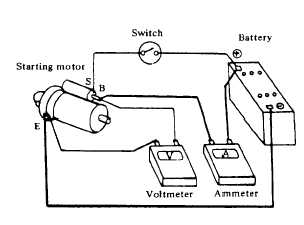

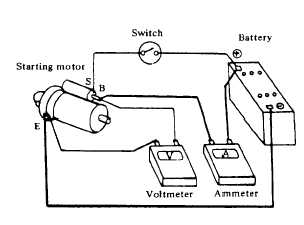

Connect the starting motor in series with a specified

(12 volts) battery and an ammeter capable of indicating

1.000 amperes.

Fig. 4-168. No-Load Test

(2)

DIAGNOSES OF TEST

(1)

Low speed with no-load and high current draw may

result from the following causes.

a.

Tight. dirty or worn bearings.

b.

Bent armature shaft or loose field probe.

c.

Shorted armature.

Check armature further.

d.

A grounded armature or field:

(a.) Remove input terminal.

(b.) Raise two negative side brushes from commutator.

(c.)

Using a circuit tester. place one probe onto yoke.

(d.) If tester indicates continuity. raise the other two

brushes and check the field and armature separately to

determine whether the field or armature is grounded.

(2)

Failure to operate with high current draw may result

from the following items.

a.

A grounded or open field coil:

Inspect connection and trace circuit with a circuit

tester.

b.

Armature coil does not operate:

Inspect commutator for excessive burning. In this

case. an arc may occur on malfunctioning commutator

when motor is operated with no-load.

c.

Burned out commutator bar:

Weak brush spring tension, broken brush spring,

rubber bush, thrust out of mica in commutator or a loose

contact between brush and commutator would cause

burned-out commutator bar.

(3)

Low current draw and low no-load speed Å would

cause high internal resistance due to loose connections,

faulty leads, dirty commutator and causes listed in item

2-C.

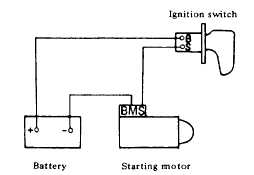

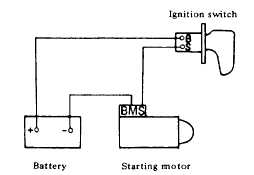

(3)

MAGNETIC SWITCH

ASSEMBLY TEST

Fig. 4-169. Magnetic Switch Assembly Test

If starting motor check is "OK," check magnetic

switch assembly. Connect cables between "negative"

battery terminal and starting motor "M" terminal,

"positive" battery terminal and starting motor "S" terminal

connecting ignition switch in series as shown in Fig. 7-

20.

With ignition switch on, measure the gap "Q"

between pinion front edge and pinion stopper.

4-100

|