| |

TM 10-3930-653-14&P

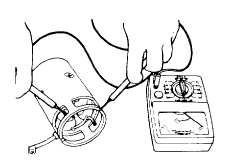

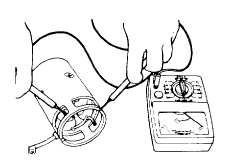

Fig. 4-159. Ground Test of Field Coil

(3)

BRUSHES AND BRUSH

LEAD WIRE

Check surface condition of brush contact and wear

of brush. If a loose contact is found, it should be

replaced.

If brush is worn and its length is less than 11.5 mm

(0.453 in), replace.

Check connection of lead clip and lead wire.

Check brush holders and spring clip to see that they

are not deformed or bent, and will properly hold brushes

against commutator.

If brushes or brush holders are dirty, they should be

cleaned.

(4)

BRUSH SPRING TENSION

Check brush spring tension with a spring scale as

shown in Fig. 7-11. Replace spring if tension is lower

than specified value.

Brush spring tension:

More than 1.4 kg (3.1 lb)

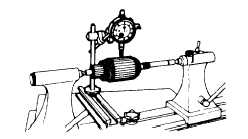

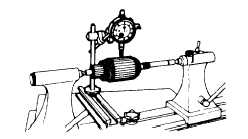

Fig. 4-160. Inspecting Brush Spring Tension

(5)

ARMATURE ASSEMBLY

Check external appearance

of

armature

and

commutator.

(1)

Measure the armature shaft for any bends with a

dial gauge. Replace armature shaft if bend exceeds

specified value.

Armature shaft bend:

Less than 0.08 mm (0.0031 in)

Fig. 4-161. Inspecting Armature Shaft for Bend

(2)

Inspect commutator. If surface of commutator is

rough, it must be sanded lightly with a No. 500 emery

cloth. Commutator must be checked also for out-of-

roundness. If out-of-roundness is more than 0.2 mm

(0.008 in), or depth of insulating mica is less than 0.2

mm

4-97

|