| |

TM 10-3930-653-14&P

(7)

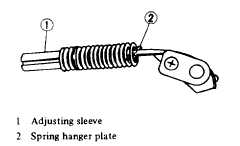

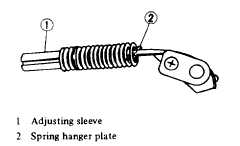

Take out cam from shaft together with cam band,

spring, and adjusting sleeve, paying attention not to

deform cam band.

Note

When disassembling further, count

active coils of spring, and keep in

mind screwed condition of spring

hanger block and adjusting sleeve

which are located at both ends of

spring,

and

relative

position

of

groove of adjusting sleeve and cam

band. These steps will serve to

facilitate adjustment after assembly.

Fig. 4-138. Mounted Condition of Spring

(8)

Remove adjusting sleeve, cam spring and cam

band.

(2)

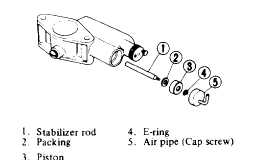

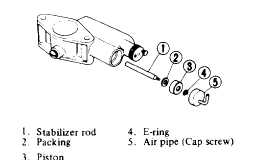

STABILIZER PISTON

Cap screw and air pipe can be taken out as a unit.

Then, remove piston.

Fig. 4-139. Stabilizer Piston Disassembled

(3)

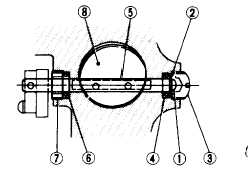

GOVERNOR VALVE

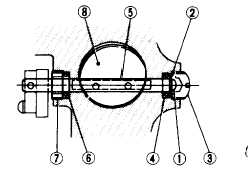

Fig. 4-140. Relative Position of Governor Valve, etc.

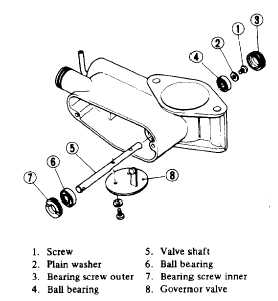

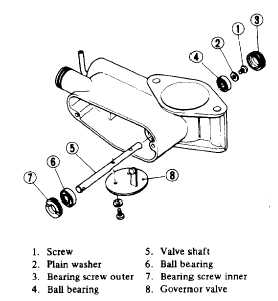

Fig. 4-141. Governor Valve, etc. Disassembled

(1)

Remove governor valve.

(2)

Remove bearing screw outer.

(3)

Remove screw and washer securing valve shaft.

(4)

Slightly tap valve shaft at cam chamber.

side, and it can be driven out together with ball bearing.

(5)

Turn bearing screw inner at cam chamber side

counterclockwise, and remove ball bearing at cam-

chamber side.

4-78

|