|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

HOSE REEL

A. INSTALLATION

CAUTION

Hold onto reel and allow It to turn

1. The hose reel must be installed in such a

slowly until spring tension is

manner as to eliminate any interference when

relieved.

mast is tilted all the way back. Reel should be

mounted so that inner flange is as close as

2. Remove four nuts and lockwashers holding

possible to mast channel (maximum 1/4"

spring can in place. With one hand, pull spring

clearance) so as to keep reel within the overall

can slowly away from flange, slide other hand

width of the truck.

between spring can and the flange to prevent

spring from Jumping out of can. Slide can from

2. The junction block must be installed on the

shaft and place it over a pan to allow any excess

center line of the middle divider of the hose reel.

oil to drain.

This permits hoses to wind properly.

3. Remove snap ring and slide flange assembly

3. Install the hoses to the hose reel and wrap

from shaft. O-rings and back-up rings are now

hoses around reel. Raise the lift truck carriage

exposed for replacement. O-rings and back-up

until the junction block is even with the hose

rings must be replaced in a set.

reel. Turn hose reel three complete turns by

pulling on hose. This provides proper tension on

4. Thoroughly lubricate o-rings and back-up rings

hose. Hold hose securely and wrap hose back

with hydraulic oil before installing hub and flange

around reel and connect to junction block.

assembly. When installing the flange assembly

back onto the shaft, use a rotary motion while

4. Raise and lower lift truck carriage and check reel

pushing flange assembly onto shaft. This will

for proper winding of hose. It may be necessary

reduce chance of nicking o-ring.

to twist hose slightly to get hose to wind

properly.

5. Replace snap ring on shaft.

B. SERVICE

6. If spring assembly is dry, or needs additional

lubrication, apply small amount of Molygrease to

Hose reel can be serviced either on or off the lift truck.

spring.

1. Raise carriage until junction block is even with

7. Slide spring can onto shaft. B. sure spring

hose reel. Disconnect hose.

enters slot on radiused side. Secure spring can

in place with four nuts and lockwashers.

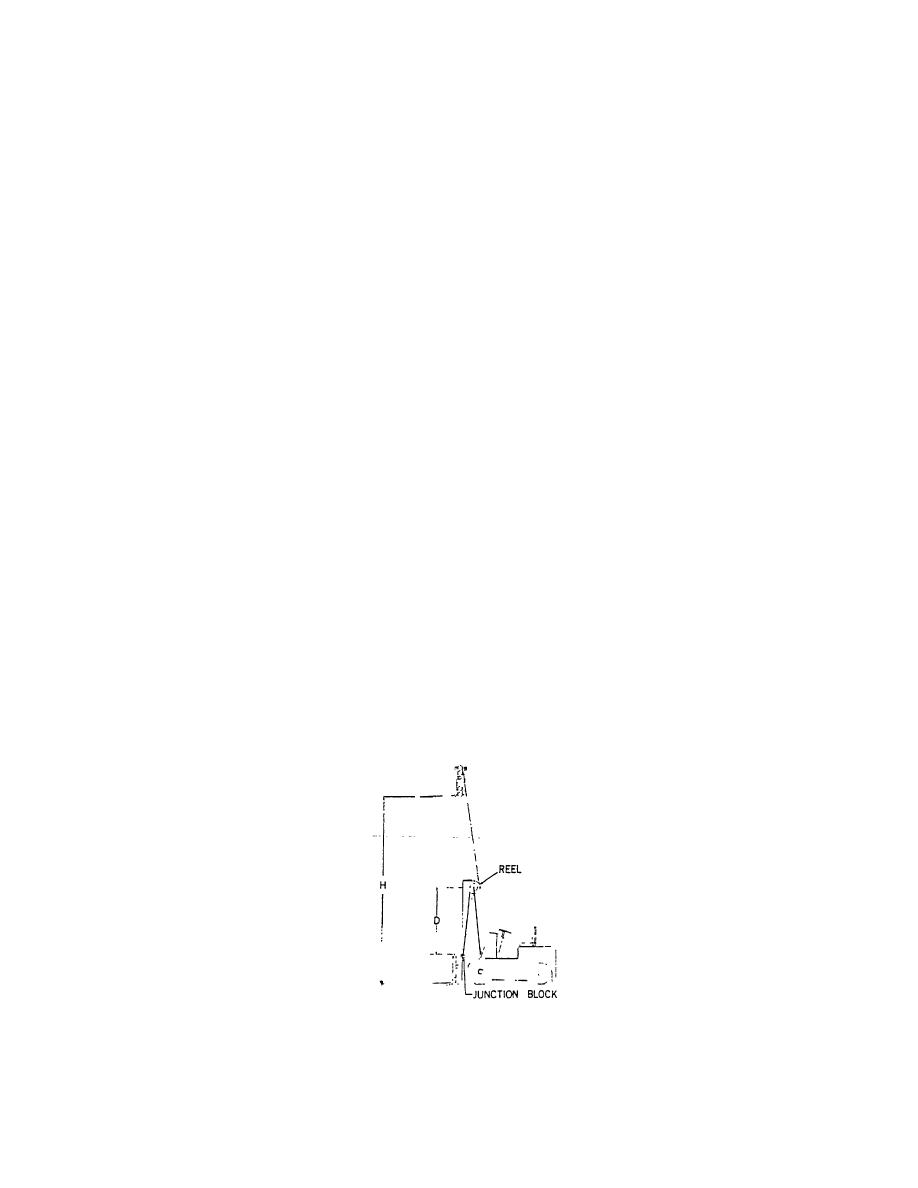

Figure 1. Hose Length Calculation

3-204

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |