|

|||

|

|

|||

|

Page Title:

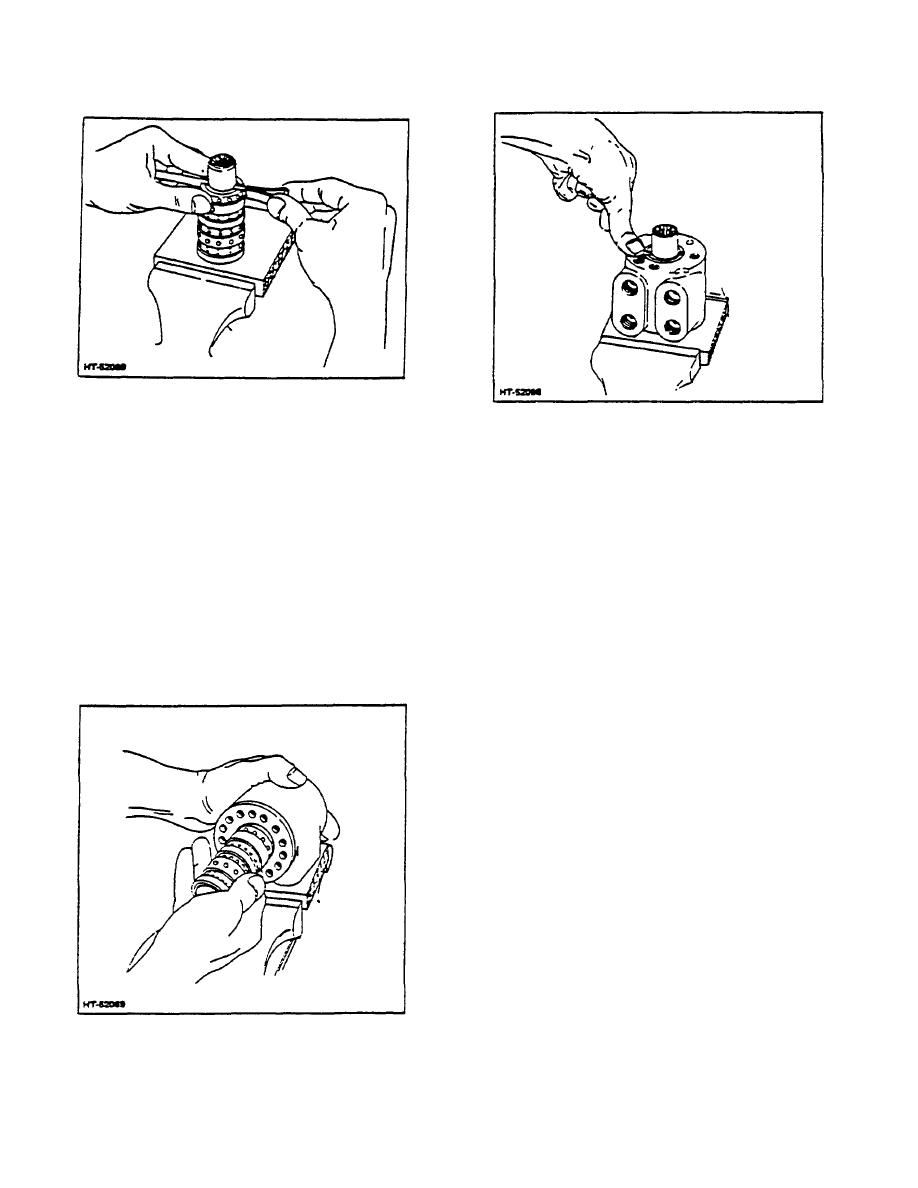

Figure 22. Installing Centering Spring Set |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Figure 22. Installing Centering Spring Set

Figure 24. Rocking Check Plug

diameter at both ends.

During Installation

9. Place the housing on a solid surface with the

this point, because the cross pin may drop into

port face down. Install the spool assembly with

the discharge groove of the housing. With spool

the splined end of the spool entering the 14-hole

assembly in this flush position, check for free

end of the housing first (Fig. 23). Push parts

rotation within the housing by turning with light

gently into place with a slight rotating motion.

finger force at the splined end. Hold the parts in

this position and place the 14-hole end of the

CAUTION

assembly on the wooden block in the vise throat

Exercise extreme care so the parts

and clamp lightly across the port face with the

do not cock out of position while

vise.

entering.

11. Install a new O-ring on the check plug, and

10. The spool assembly should be installed within

install the plug in the housing, (Fig. 24). Exert a

the housing bore until it is flush with the 14-hole

steady pressure on the plug, rocking it slightly so

end of the housing. Do not install the spool

the O-ring feeds in smoothly without cutting.

assembly beyond

12. Insert the cap locator bushing, large O.D.

chamfer up, partially into the housing. Rotate

the bushing with the fingers to seat It flatly and

smoothly against the spool assembly.

13. Install new mounting plate and shaft seals.

Push each seal carefully into the seal groove

with the fingers. The seal groove is slightly

smaller than the seal to provide adequate

sealing.

NOTE

The thin oil seal at exterior of

mounting plate is used only to seal

out dirt and generally does not need

replacement.

However, if it is

replaced, it must be pressed into the

counterbore so that the lip is directed

away from the unit.

14. Place the mounting plate subassembly over the

spool shaft and slice it down smoothly in place

over the-cap locator bushing so that seals will

Figure 23. Installing Spool Assembly

not be disrupted in assembly (Fig. 25).

3-168

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |