|

|||

|

|

|||

|

Page Title:

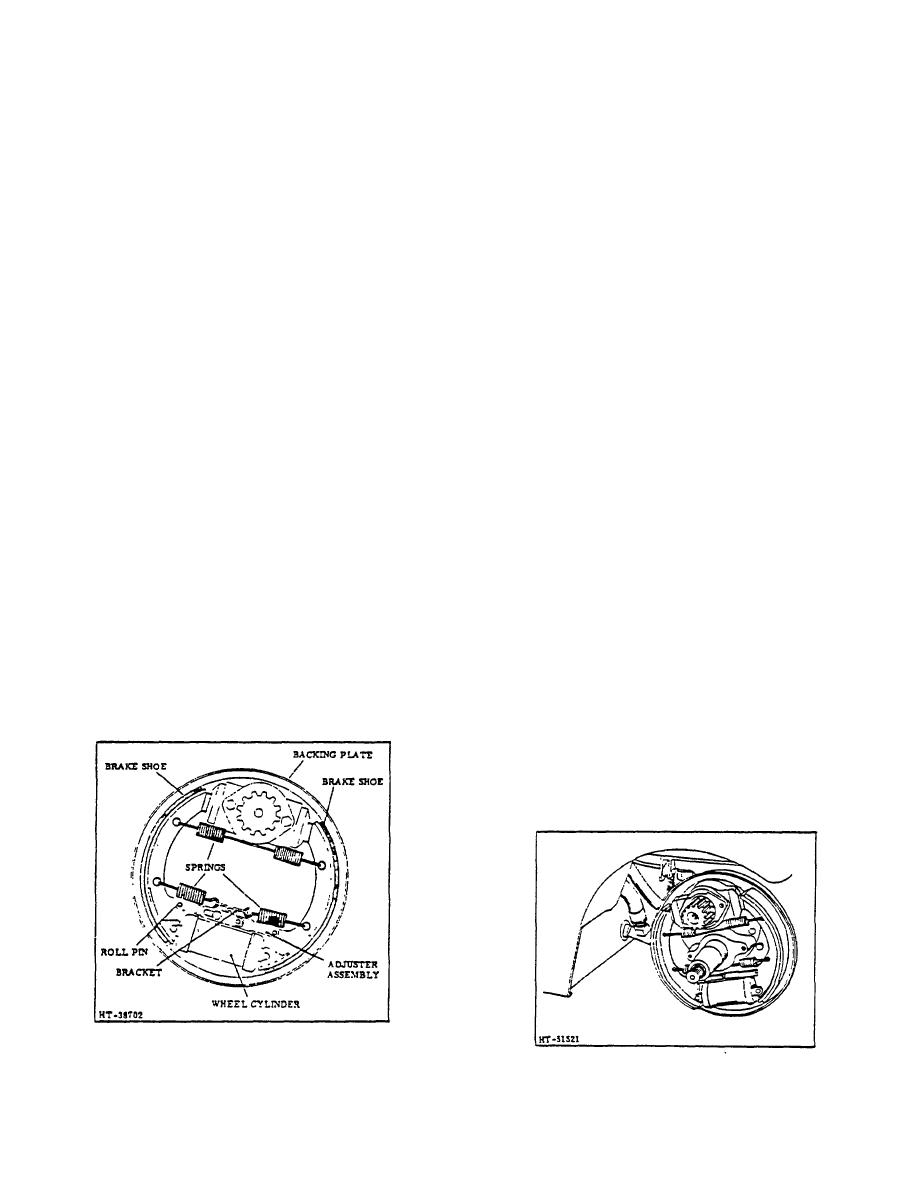

Brake Shoes - Self-Adjusting |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

hydraulic brake system requires a "solid column of fluid"

the two slide assemblies of the self adjuster is

and the fluid should possess essential protective

great enough to prevent the brake shoe springs

properties which safeguard the system.

from fully retracting the self adjuster, but not

great enough to prevent the hydraulic pressure

from expanding it. The self-adjuster assembly is

CAUTION

mounted to the brake shoes with roll pins. The

Because of the importance of the

roll pin holes in the brake shoes are 1/32"

fluid used in the brake hydraulic

oversize to provide proper working clearance

system, use only premium quality,

between the brake shoe lining and drum.

heavy duty brake fluid with an

extreme

heat-cold

range

that

conforms to SAE specification 70-R1.

CAUTION

Exercise care when self-adjuster is

1. Operation of Wheel Cylinders and Brake Shoes

handled or installed. Do not bend the

tangs of the slide assemblies in any

Hydraulic fluid entering the wheel cylinders from

way because the holes for the roll

the master cylinder forces pistons to move

pins must be parallel with each other.

individually and in opposed directions. This

If the holes are not parallel, the roll

piston travel expands the brake shoes. As the

pins will tie at a slight angle through

pressure increases, the piston cup lips are

the mounting holes in the brake

forced more tightly against the cylinder wall,

shoes. Improper alignment of the roll

effecting a positive fluid seal, neglecting minor

pins could lead to improper brake

friction losses. The controlled actuating force is

shoe retraction due to lack of proper

equal to and varies with the hydraulic pressure

roll pin clearance in the brake shoe

exerted against each square inch of the piston

holes.

This in turn could create

face.

brake shoe drag on the drum.

The pistons are returned to an "off" position by

In order for the self-adjusting brakes to operate

the force of the brake shoe retracting springs.

properly, the self adjuster assembly must be

The piston cup lips are pressed against the

properly torqued. If it becomes necessary to

cylinder walls by natural resiliency and system

remove and disassemble the self adjuster in the

residual pressure to seal against fluid or air

field, then it must be carefully reassembled and

leaks.

The hydraulic pistons of the wheel

installed as outlined In the installation section.

cylinders follow the brake shoes as they expand

into the drums.

B. REMOVAL

2. Brake Shoes - Self-Adjusting

Before removing drive wheels.

drive truck (loaded

preferred) and make an eat, rolling stop. Any pulsation

The brake shoes are self-adjusting through the

or vibration on the foot pedal indicates out-of-round

use of a friction operated self-adjuster in each

drums. In order to perform any service on components

drive wheel. The friction between

of the drive wheel brakes, disassemble according to the

following instructions.

1. Remove drive wheel assembly and components

to expose the wheel cylinders and brake shoes

(Figure 3).

(Refer to DRIVE WHEEL

REMOVAL, MAINTENANCE MANUAL.)

Figure 2. Self-Adjusting Brakes (Typical)

Figure 3. Dust Shield Removed

3-148

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |