|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

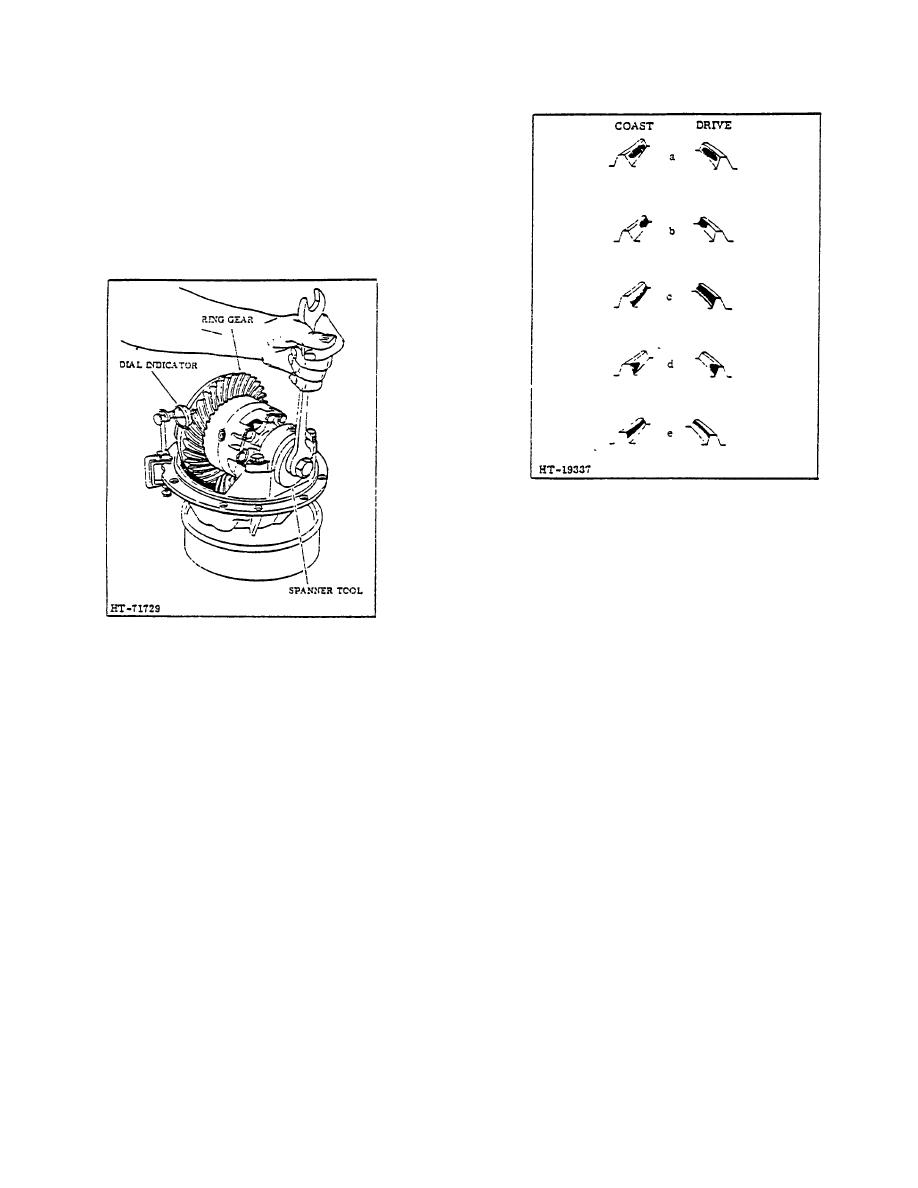

4. Adjust the ring gear laterally for a backlash

adjustment of .005" to .010" (backlash etched on

gear), by means of the differential side bearing

adjusting nuts. To Increase backlash, loosen

adjusting nut nearest to ring gear and tighten

opposite nut. To decrease backlash, reverse

the operation. Differential side bearings must

not be set any tighter than that which will

produce a maximum pull of 3 to 5 lbs. on a string

wrapped around the differential case.

Figure 18. Differential Tooth Pattern

Explanation of Figure 18

a. Correct adjustment.

b. Heavy contact on toe of tooth. To correct,

move ring gear away from pinion. Move

pinion towards ring gear to again secure

correct backlash.

Figure 17. Adjusting Backlash

c. Bearing too low. Heavy contact on flank

5. With the drive pinion properly installed and

of tooth. To correct, move pinion away

adjusted. rotate the pinion and hold back on the

from ring gear until contact comes to full

ring ,ear to create the effect of a load. After

working depth of gear tooth without

several rotations of the drive pinion, inspect the

bearing contact at flank. Move ring gear

teeth of the pinion where the paint has been

towards pinion to secure proper backlash.

removed by gear contact. Compare the tooth

bearing (area where paint was removed), with

d. Heavy contact at heel of tooth. To correct,

Figure 18. The tooth bearing should start at a

move ring gear towards pinion. Move

point about 1/32 to 1/16 inch from the top of the

pinion away from gear to obtain correct

tooth and continue downward to a point about

backlash.

1/32 to 1/16 Inch from the bottom of the tooth.

e. Shows heavy contact on tooth face. Move

NOTE

pinion towards gear .'l contact covers flank

Do not be concerned with the amount of

of tooth without breaking contact at face.

paint removed from the front toward the rear

Move gear away from pinion to secure

of the tooth. The amount of paint removed

correct backlash.

is determined by the amount of load applied

while rotating the drive pinion and ring gear.

6. .After proper backlash and tooth pattern are

The tooth bearing should always be more

obtained, fully tighten capscrews holding bearing

toward the toe end. or a toe bearing.

caps in place and wire in position.

7. Install adj usting nut lock and align with hole in

adjusting nut. Secure to cap with capscrew and

lockwasher.

3-145

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |