|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14 & P

d. Failure to operate with no current draw

indicates:

(1) Open field circuit.

This can be

checked after disassembly by

inspecting internal connections and

tracing circuit with a test lamp.

(2) Open armature coils. Inspect the

commutator for badly burned bars

after disassembly.

(3) Broken

brush

springs,

worn

brushes, high insulation between

the commutator bars or other

causes which would prevent good

contact between the brushes and

commutator.

e. Low no-load speed and low current draw

indicates:

(1) High internal resistance due to poor

Figure 3-3. Resistance Test Hookup

connections, defective leads, dirty

commutator and causes listed in

Step "d".

3. Remove the commutator end frame and field

frame assembly.

f. High free speed and high current draw

indicate shorted fields. If shorted fields

4. Remove the solenoid and shift lever assembly

are suspected, replace the field coil

from the drive housing.

assembly and check for improved

performance.

5. Remove the armature assembly from the drive

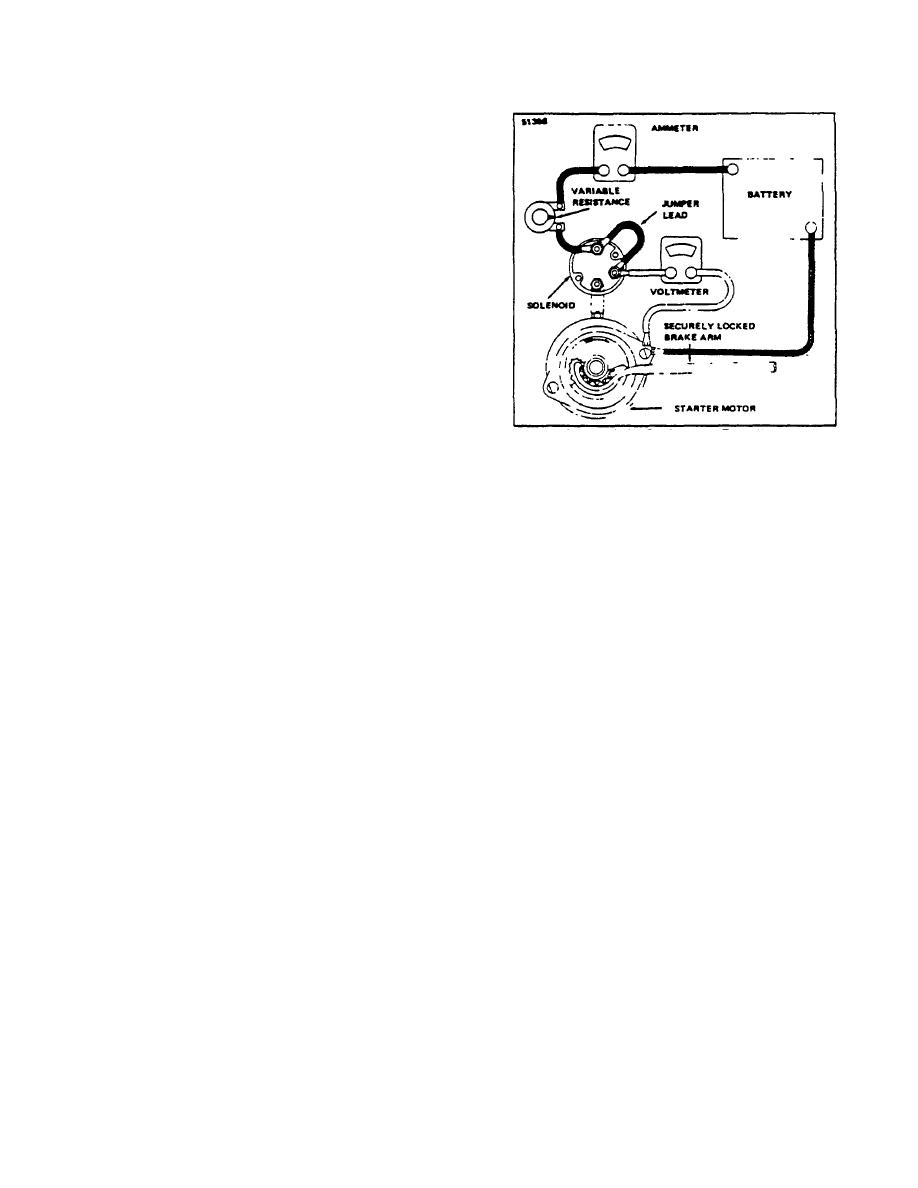

2. Resistance Test

housing.

This test requires equipment as illustrated

6. Remove the thrust collar from the armature

in Figure 3-3. Lock the pinion securely so

shaft.

it cannot rotate.

When the specified

voltage is applied, the current should fall

in a range as Indicated in Starter Motor

7. Remove the pinion from the armature by sliding

Test Specification Chart. A high current

a metal cylinder onto the shaft.

Using a

indicates shorted or grounded conductors,

hammer, strike the metal cylinder against the

and a low current indicates excessive

retainer, driving the retainer toward the armature

resistance.

core and off the snap ring. Refer to Figure 3-4.

F. DISASSEMBLY

8. Remove the snap ring from the groove in the

If the starter does not perform in accordance with the

armature shaft.

specifications, it may need to be disassembled for

further testing of the components. Normally the starter

G. INSPECT AND REPAIR

motor should be disassembled only so far as is

necessary to make repair or replacement of the

1. Brushes and Brush Holders Inspect the brushes

defective parts.

Following are recommended

for wear. If they are worn down to one-half their

instructions for disassembly procedure.

original length, when compared with a new

1. Disconnect the field coil connections from the

brush, they should be replaced. Make certain

solenoid motor terminal.

the brush holders are clean and the brushes are

not binding in the holders.

The full brush

2. Remove the thru-bolts.

surface should ride on the commutator with a

spring tension of 35 oz., to give good, firm

contact. Brush leads and screws should be tight

and clean.

R-146-1

3-94

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |