|

|||

|

|

|||

|

Page Title:

PREPARING CYLINDER WALLS FOR RE-RINGING OR RE-BORING. |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

11. Check in same manner the top of the ring travel

area, approximately 1/4" below the shoulder.

12. The maximum difference in checks 10 and 11

indicates the amount of cylinder bore wear. If

this difference is less than .008", re-ringing will

be suitable, and if over .008" re-boring is

recommended.

D. PREPARING CYLINDER WALLS FOR RE-RINGING

OR RE-BORING.

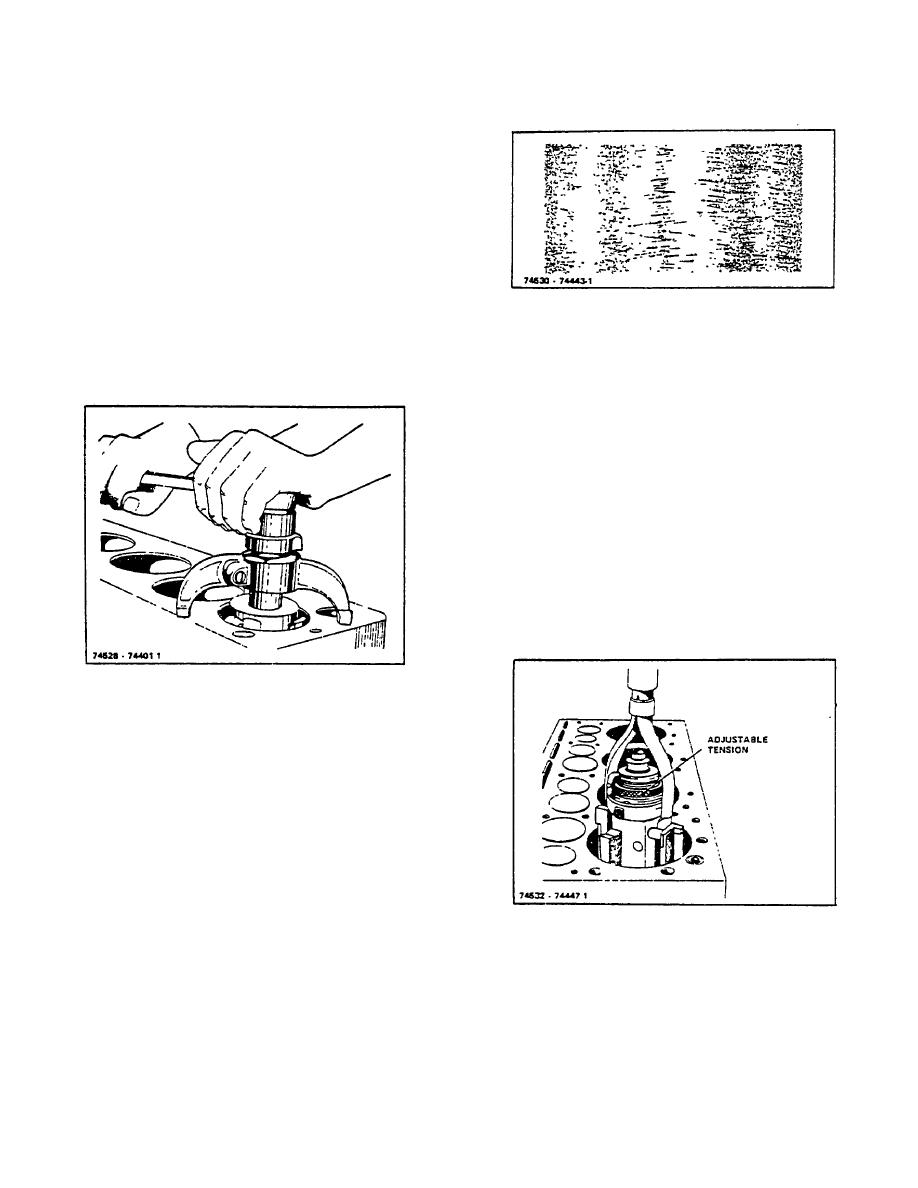

Figure 11-4. Desirable Cross Hatch Pattern After

1. Ridge ream the cylinders to remove the unworn

Cylinder Hone.

area at the top so that new rings, when

assembled, will not bump and distort both

E. GLAZE BREAKING OPERATION

themselves and the piston lands (Figure 11-3).

It is important to remove the glaze on the cylinder bores

by using a cylinder hone which has an adjustable stone

tension (Figure 11-5). Glaze breaking assures quick

seating of new piston rings. If the cylinder glaze is not

removed, there will be no assurance as to when the

rings will begin to function properly and control the oil;

this is especially true when chrome rings are used.

The following step by step procedure is recommended:

1. When the crankshaft has not been removed,

cover the entire crankshaft with a clean, slightly

oily cloth to prevent abrasives and dirt from

getting on the crankshaft.

Figure 11-3. Ridge Reaming Top of Cylinder Bore

Several good makes of ridge reamers are

available which will ream the top of the bore in

direct relation to the worn area so that should

the worn area be off center slightly there will be

no partial ridge remaining.

2. When re-boring the cylinders allow .002" for

finishing by honing.

3. To get the correct cross hatch pattern (Figure 11-4)

with a cylinder hone, use a top quality electric drill

with a speed of 500 RPM or less.

Figure 11-5. Honing Cylinders

R-104-1

3-41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |