|

|||

|

|

|||

|

Page Title:

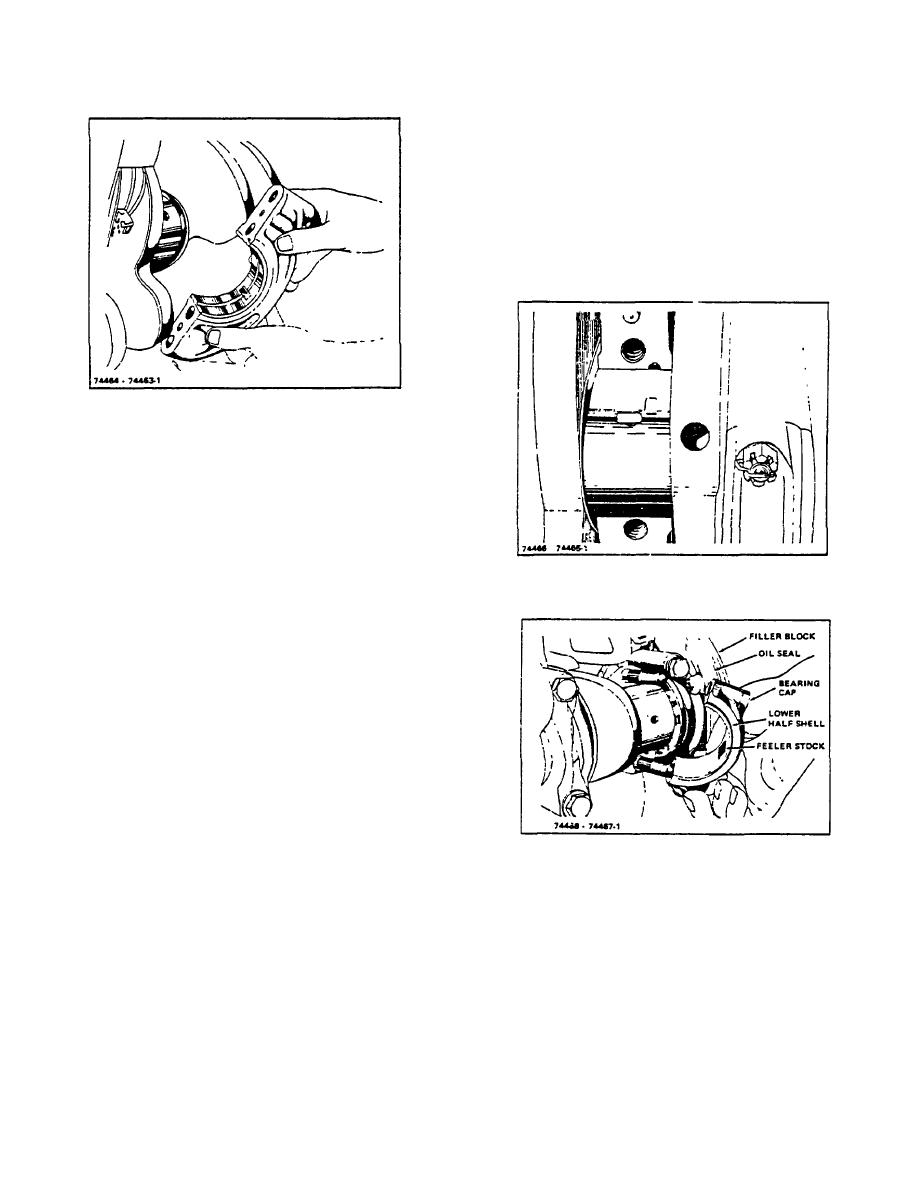

Figure 6-11. Checking Bearing Clearance with Feeler Stock |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

bearing bolts are tightened and attempting to move

the rod from side to side in the direction of end

clearance. If the crank pin is not worn. a well-fit

bearing is usually just loose enough to be "snapped"

from side to side, without actually feeling so loose as

to push easily. Sometimes a slightly snug bearing will

not move under pressure but will move readily under

light blows from a soft-faced hammer. This condition

is usually considered satisfactory, providing the

engine is given adequate break-in time.

Figure 6-11. Checking Bearing Clearance with Feeler

Stock

no more in thickness than, the maximum clearance

specified, neither the crankshaft nor the bearing is

worn excessively as far as clearance is concerned.

When using new bearings with a crankshaft that is

not worn, checking may be done with a piece of feeler

stock as outlined above. This should lock up the

Figure 6-12. Replacing Bearing

crankshaft, making it possible to turn only by use of a

bar or wrench.

Generally, the test on main bearings consists of

tightening each bearing cap in turn, and turning the

crankshaft to detect binding.

It is emphasized that any unusual bending or run-nut

in a crankshaft makes it impossible to fit bearings

accurately. For this reason, the time spent in making

a run-out check is well worth while.

Magnetic

inspection of the crankshaft and other stressed parts

is also recommended if the proper equipment is

available.

Connecting rod bearings and crank pins may be

Figure 6-13. Checking Connecting Rod Bearing with

checked in the same manner as main bearings with

one exception: do not try to turn the crankshaft when

Feeler Stock

the connecting rod bearing is tightened on it with a

piece of feeler gauge assembled; rather, try to move

3. Bearing Installation

the connecting rod from side to side (Figures 6-12

and 6-13).

NOTE

Coat all running surfaces with clean,

The familiar test of connecting rod bearing clearance

fresh engine oil when installing

consists of manually gripping the rod cap after the

bearings.

R-104-1

3-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |