|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

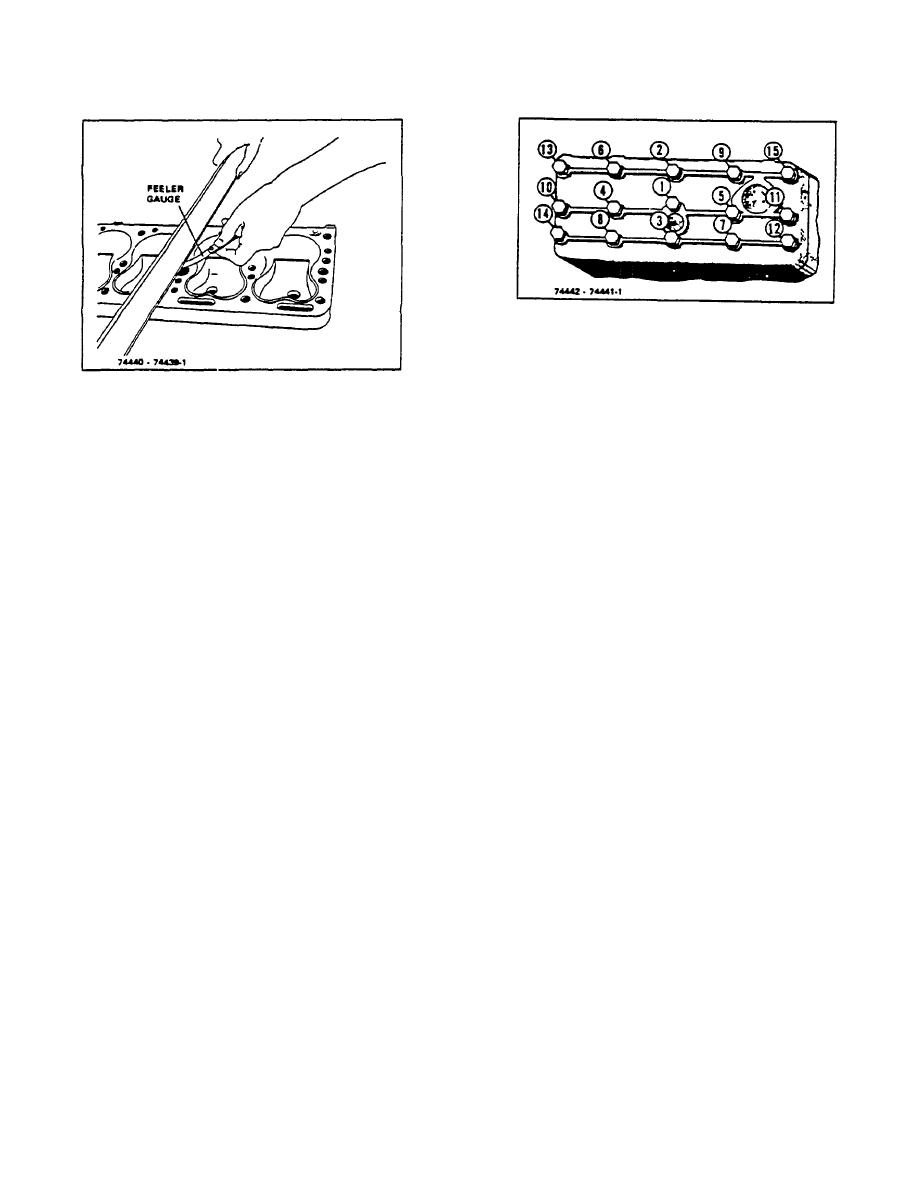

Figure 5-4. Cylinder Head Torquing Sequence

2. Refer to Figure 5-4 for correct cylinder head

capscrew torquing sequence.

Install two

4908605-1 capscrews at locations 6 and 12. All

Figure 5-3. Checking Cylinder Head Flatness Crosswise

other capscrews are identical.

D. INSTALLATION

3. Install distributor and secure it with clamp and

1. Install new head gasket and replace cylinder

capscrew.

head on cylinder block.

4. Remove covering from spark plug ports and,

after checking the insulation for cracks and

NOTE

verifying correct gap, reinstall spark plugs.

Capscrews should be tightened in

successive stages and in such order

5. Attach respective spark plug ignition wiring to

as will ensure even pressure over the

plug caps.

entire surface of the cylinder head

and gasket.

If all the outside

6. Connect temperature sender wire.

capscrews are pulled up first, instead

of the center ones, the head will be

7. Secure water by-pass tube to water pump. Do

cocked and the gasket will not fit

not over-tighten connector.

tight enough to prevent burning or

blowing out between cylinders. A

8. Re-install upper radiator hose, thermostat and

good torque wrench is recommended

attaching clamps.

for this purpose. It is good practice

to hold tension on each capscrew for

9. Refer to TOPIC 3 and install the manifold.

a few seconds before releasing the

wrench.

10. Add engine oil, allowing for extra halfquart if oil

filter was changed.

It is recommended that several

passes be made in tightening down

11. Close radiator and cylinder block water drain

the head so as to avoid any warpage.

cocks.

At the first pass apply approximately

one-half of the recommended torque,

12. Refill radiator.

and then increase the torque one-half

each succeeding pass until the

13. Refer to TOPIC 16.

ENGINE

RUN-IN

recommended torque is attained.

SCHEDULE for compression check.

Torque all capscrews to 70-75 lb. ft.

R-104-1

3-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |