|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

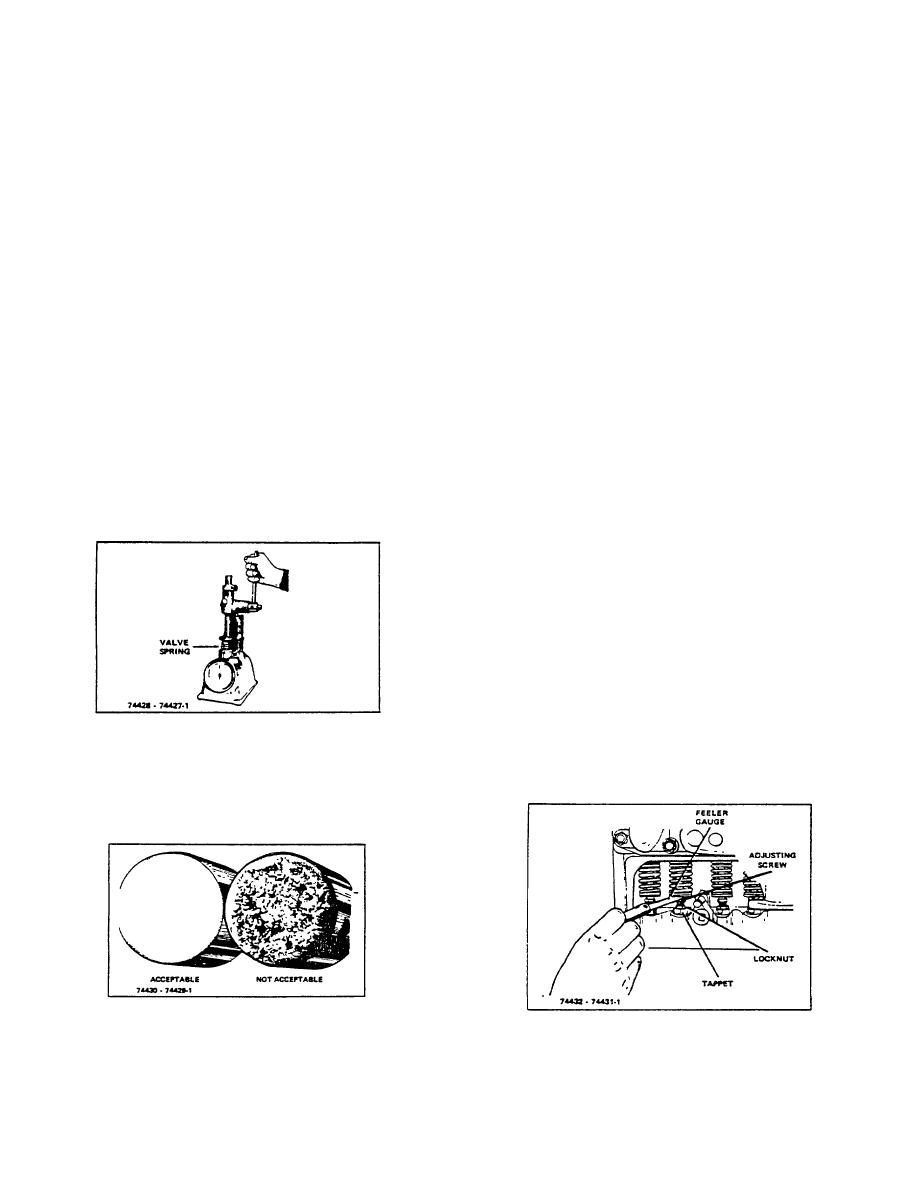

Inspect each tappet carefully. A slightly pitted

CAUTION

contact face is acceptable; more than that calls for

Never allow valves to set down

replacement of the tappet. See Figure 4-14.

inside the seat.

After the narrowed-down seat is brought within

Check the tappet outside

diameter with

specifications, the seat should be retouched

micrometers to determine if

replacement is

lightly with the original stone to remove burrs

necessary because of wear.

or feathered edge.

The tappets ride in a tappet bore in the cylinder

block. The tappet bore may be reamed oversize,

"A poor valve grinding job cannot

and oversize tappets installed. Oversize tappets

be corrected by valve lapping."

are available as required.

Coat the valve stem with a light film

of engine oil.

The following specifications apply:

5. Valve Springs

Tappet Outside Diameter..............

.9990"

Check all valve springs on a spring tester

Bore in Block Diameter .................

1.0000"

(Figure 4-13) to make sure they meet

Total Maximum

specifications regarding weight and length.

Wear Limit .............................

.0050"

When compressed to the "valve open" or

"valve closed" length, new springs must fall

E. VALVE/VALVE TAPPET CLEARANCE ADJUSTMENT

within specifications. Refer to TOPIC 1. FITS

AND TOLERANCES. Used springs showing

Accurate valve clearance settings materially prolong

more than 10% loss must be replaced.

engine life and aid performance. Excessive clearances are

detrimental to cams and tappets as well as to the rest of

the mechanism. On the other hand, when clearances are

too low, timing is again disturbed, and the possibility of

burned valves becomes much greater.

Valve tappet clearances should be as follows

(See Figure 4-15) :

Intake..........................................

012"

Exhaust.......................................

020"

To adjust tappet clearances proceed as follows

Figure 4-13. Valve Spring Tester

(See Figure 4-16) :

Reassemble the valves and springs in the

1. Disconnect the high tension coil wire to prevent

block with the retainer and retainer lock.

accidental starting of the engine.

6. Valve Tappets

Figure 4-15. Checking Tappet Clearance -

Figure 4-14. Valve Tappet Wear Comparison

Engine at Room Temperature.

R-104-1

3-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |