|

|||

|

|

|||

|

Page Title:

TOPIC 1. LUBRICANT SPECIFICATIONS |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

LUBRICANT AND FUEL SPECIFICATIONS

TOPIC 1. LUBRICANT SPECIFICATIONS

A. ENGINE LUBRICATING OIL

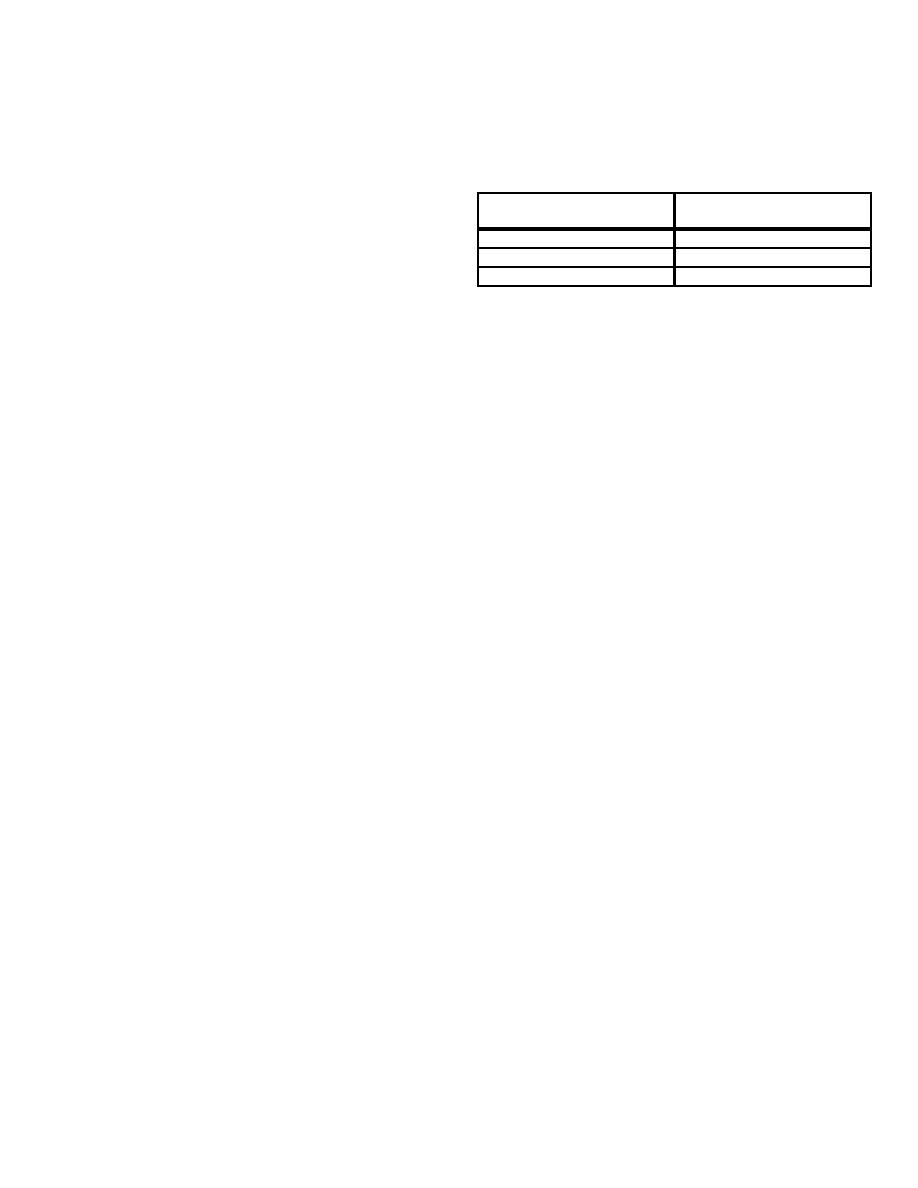

Atmospheric

The basic requirements for lubricating oils used in Allis-

Temperature

Viscosity

Chalmers engines are:

SAE 20

Below 32F

SAE 30

32F to 90F

1. Maintain pistons, rings, and other moving parts

SAE 40

Above 90 F

in a carbon free, varnish free, and clean

condition.

Our recommendation of 100 hours for filter and oil

2. Maintain enough body to satisfactorily lubricate

change periods is based on the use 6f high quality oils

the moving parts at maximum oil temperatures.

and 85% average engine loads with the engine in good

3. Prevent bearing corrosion. Counteract corrosive

adjustment and operating with the coolant and

products of combustion or contaminants in the

lubricating oil at normal operating temperature.

fuel.

Variations from the considered normal operating

4. Promote general cleanliness within the engine.

conditions must be compensated for by the use of

premium grade oils or more frequent oil change and filter

The American Petroleum Institute has several service

change periods. or both.

classifications for oils used in gasoline and L. P. gas

engines; they are SA. SB, SD, and SE. For diesel

Our recommended oil change periods are based on

engines, the classifications are CA, CB. and CD.

what experience has shown to be conservative and safe

hours of operation between oil changes. Actual testing

SERVICE SA and CA: Service typical of engines used

of the lubricating oil in any particular engine application

under light and favorable operating conditions, the

at each S to 10 hours operation after 100 hours

engines having no special lubrication requirements and

operation to determine the condition of the oil may allow

having no design characteristics sensitive to deposit

extending the oil change periods. This testing service is

formation.

provided by most major oil companies.

It is

recommended to take advantage of this service.

SERVICE SB and CB: Service typical of engines used

under moderate to severe operating conditions.

B. HYDRAULIC SYSTEM OIL

but presenting problems of deposit corrosion control

Use a hydraulic oil that conforms to Allis-Chalmers

when lubricating oil temperatures are high.

specification H-100 or SAE 10 SE engine oil (or MIL-L-

2104B) in the hydraulic system.

SERVICE SD and CD: Service typical of engines used

under unfavorable or severe types of operating

The hydraulic oil must be fortified with special rust and

conditions and where there are special lubrication

oxidation inhibitors, plus anti-wear ingredients. and

requirements for deposit. wear, or bearing corrosion

treated to minimize foaming. The hydraulic oil must

control, due to operating conditions, or engine design, or

conform to the following in Allis-Chalmers specification

fuel characteristics.

H-100:

SERVICE SE: Oils designed for this service provide

Viscosity at 100F SUS ........................... 150 - 170 secs

more protection against oil oxidation. high temperature

Viscosity Index .................................................... 90 min

engine deposits, rust, and corrosion in gasoline engines

Flash Point ....................................................370F min

than oils which are satisfactory for classification SD.

Neutralization No. (mgs KOH/g oil).......................... 0.60

Aniline Point ............................................... 180 - 220F

Generally, SERVICE SB will apply to the gasoline or L.

Oxidation Stability (hrs. to neut. No. 1.0 max).......... 1500

P. gas engines, and SERVICE CB will apply to the diesel

Rust Test ............................................................. Pass

engines.

Copper Strip Corrosion (3 Hours at 212F) ........ Pass 2B

Pour Point .................................................... -20F max

Use oils of the following viscosities:

2-116

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |