|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

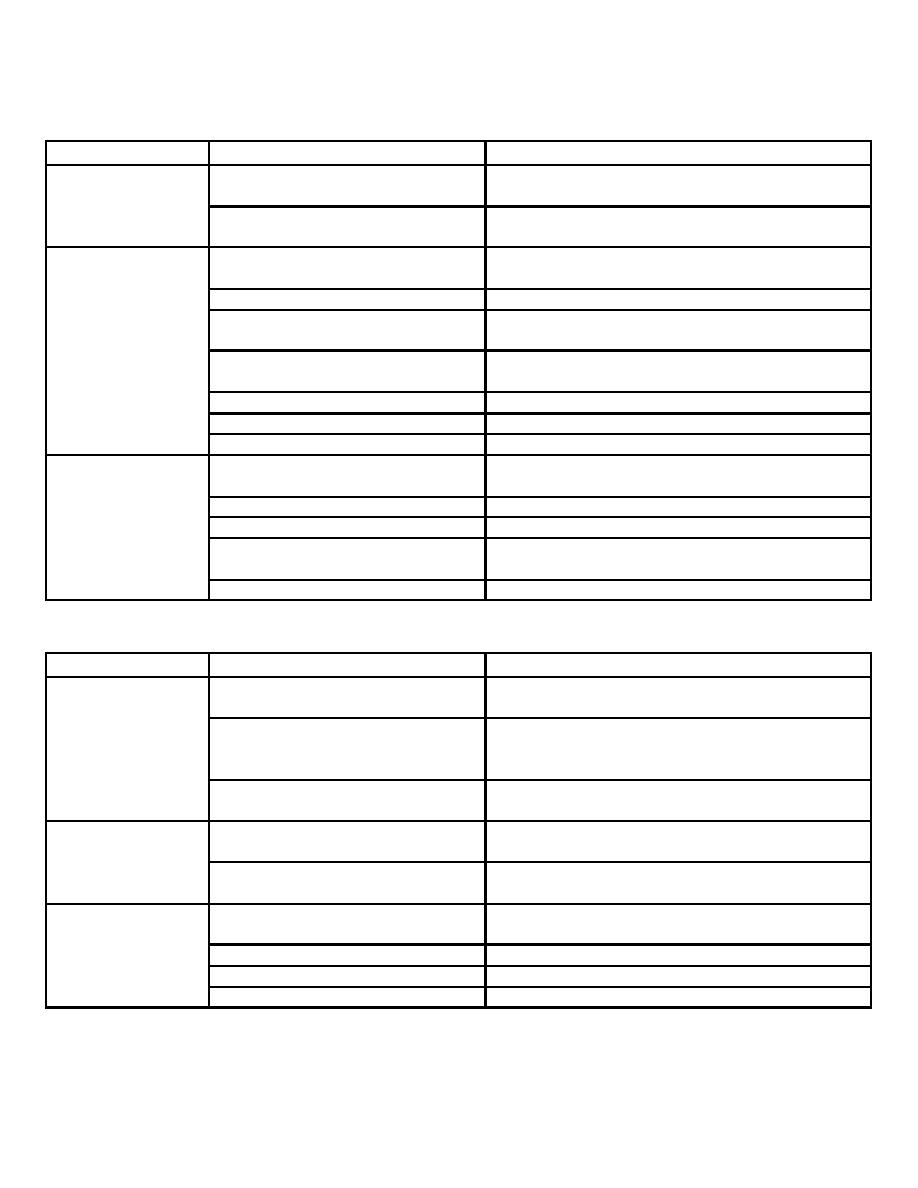

C. HYDRAULIC SYSTEM (CONT)

TROUBLE

PROBABLE CAUSE

POSSIBLE SOLUTION

Load creeps-

Leak in control valve.

Check for worn or damaged plungers.

tilting or

lowering.

Leaks in oil lines.

Tighten all connections or replace damaged

(Continued)

lines.

Noisy hydraulic

Insufficient or no oil.

Check tank for proper oil level or restricted

pump.

suction line.

Air leaks.

Tighten intake connections.

Air bubbles in intake oil.

Use hydraulic oil with antifoaming character-

istics.

Oil reservoir breather re-

Replace breather.

stricted.

Coupling misalignment.

Realign.

Pump head loose.

Tighten.

Worn or broken parts.

Replace.

Hydraulic-oil

Pump too tight alter overhaul.

Remove and repair.

overheating.

Restricted lines.

Check and repair.

Relief valve set too high.

Valve should be set as recommended.

Incorrect oil.

Drain. replace filter and use only recom-

mended oil.

Internal oil leakage.

Repair or replace pump.

D. DRIVE UNIT

TROUBLE

PROBABLE CAUSE

POSSIBLE SOLUTION

Failure to op-

Broken jackshaft/axleshaft.

Replace jackshaft/axleshaft.

erate.

Teeth broken out of jackshaft.

Replace jackshaft, bull gear. axleshaft, or

bull gear. axleshaft. or

planetary.

planetary cluster.

Broken teeth on ring gear or

Replace ring gear and pinion.

pinion.

Axle noise on

Excessive wear at ring gear

Adjust. if possible. or replace.

drive or coast.

and pinion.

Worn pinion gears or side gears

Replace worn gears.

in differential case.

Continuous

Excessive wear in gears.

Replace worn parts.

axle noise.

Lack of lubrication.

Lubricate with specified lubricant.

Uneven tire wear.

Replace tires.

Worn or damaged bearing.

Replace bearings.

2-109

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |