|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

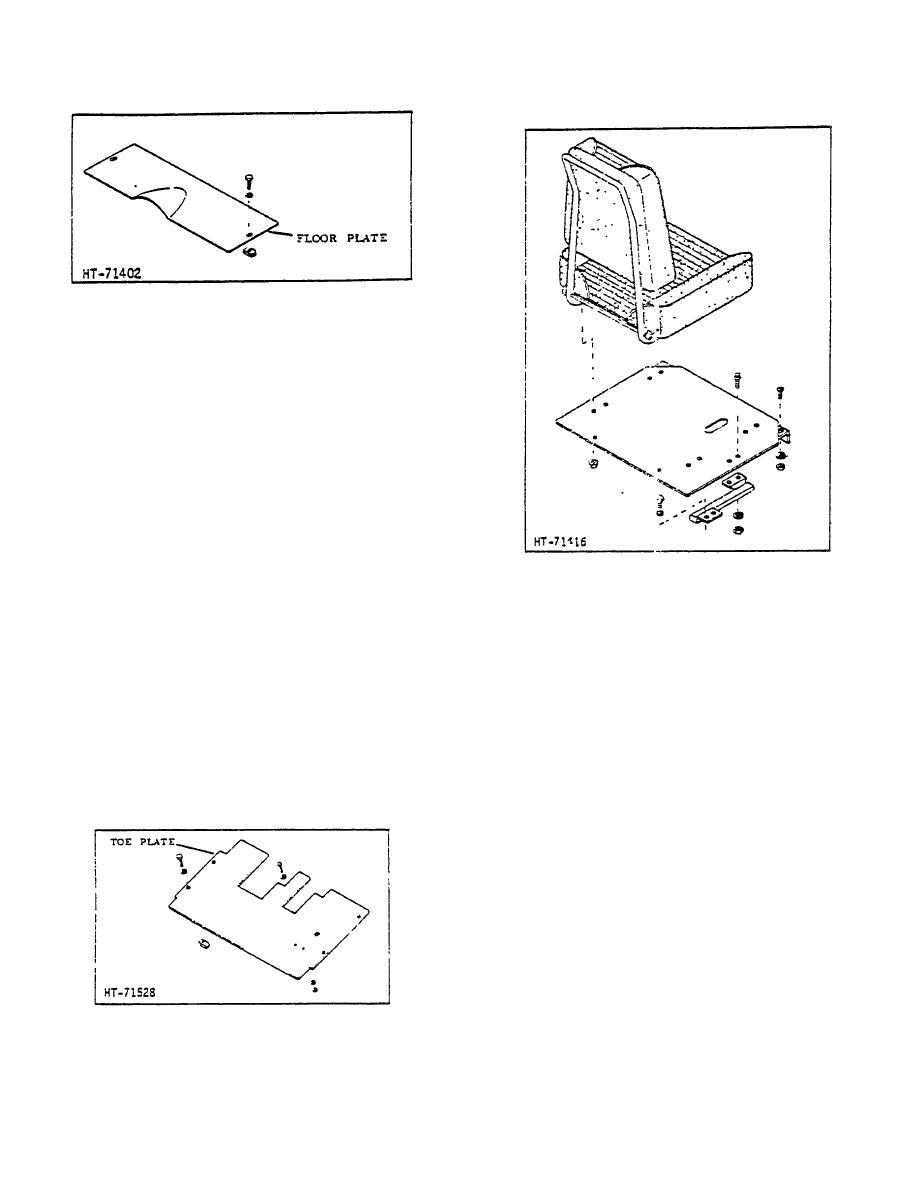

Figure 6. Floor Plate

A. HOOD AND SIDE PANELS

Figures 4 and 5 represent a non-specific., general

representation of the engine hood, side panels and front

engine grille typical to all lift truck models.

1. The side panels are normally secured with a

spring type latch, the disengagement of which

allows side panel -removal for service to engine.

2. The hood, cross assemblies, seat support

assembly, and front grille are all attached with

capscrews, lockwashers and nuts.

To

disassemble, simply study the inter-relationship

of the parts of interest and remove the

Figure 8. Seat Assembly

capscrews, lockwashers, nuts and parts

required for access to component requiring

1. To remove floor and/or toe plate, simply remove

service.

capscrews and lockwashers and lift plate away

from truck.

3. Reverse disassembly procedure, as required, to

reassemble.

2. To install either or both plates, place in correct

position, align holes and replace capscrews and

B. FLOOR AND TOE PLATE

lockwashers.

Refer to Figures 6 and 7 to locate the floor and toe

plates. As a rule the floor and toe plates will require no

C. SEAT ASSEMBLY

maintenance whatever, but are removed during normal

maintenance routine to service items such as

The operator's seat has two vinyl covered, foam rubber

transmission, steering column, brake master cylinder,

cushions; one serves as a backrest and the other as the

etc.

seat cushion. These cushions are contour for maximum

comfort and reduced sliding.

The seat assembly (Fig. 8) has a forward/backward

adjustment to allow for optimum pedal reach as desired

by operator.

1. Should it become me necessary to remove the

operator's seat, simply remove the seat base

assembly mounting capscrews and lift from

truck.

2. To replace the operator's seat, place assembly

in relative mounting position, align all holes and

Figure 7. Toe Plate

insert and secure capscrews and lockwashers.

2-95

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |