|

|||

|

|

|||

|

Page Title:

TOPIC 1. HYDRAULIC SYSTEM SERVICE |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 1. HYDRAULIC SYSTEM SERVICE

A. GENERAL

The hydraulic system provides the means by which the

lift, tilt, and accessory operations are controlled.

Included in the system is an engine driven, gear type

pump that supplies hydraulic oil to the control valve.

From the control valve, the flow of hydraulic oil under

pressure is directed to the appropriate cylinders. The

hydraulic oil is cleaned by a filter located between the

control valve and reservoir. The reservoir provides an

adequate supply of hydraulic oil to the pump plus an

ample reserve. A suction port is provided at the bottom

of the reservoir to gravity feed oil to the hydraulic pump.

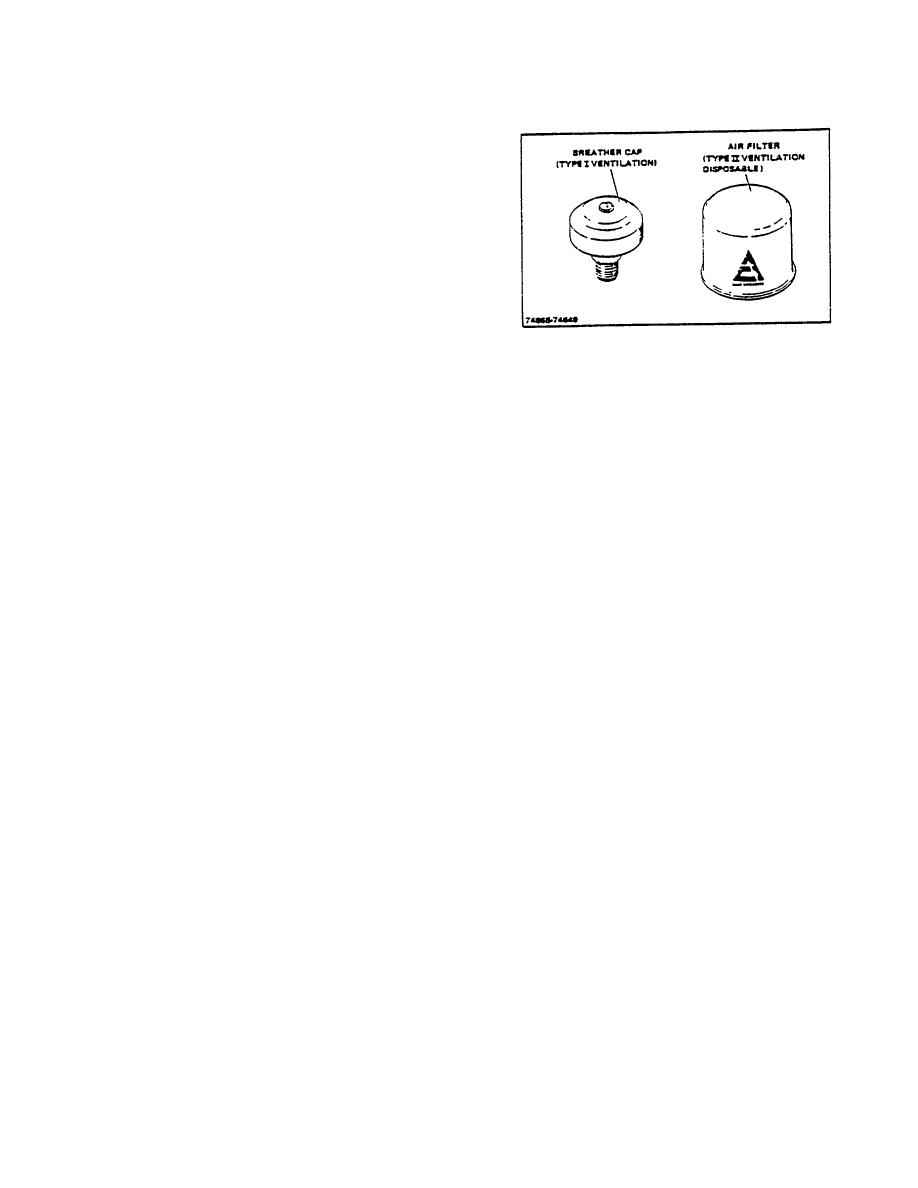

Figure 1-1. Reservoir Ventilation

B. GENERAL MAINTENANCE

8. Periodically check the pump and control valve

It is essential that personnel responsible for the care of

mounting hardware for tightness.

the unit adhere to the following general maintenance

9. Replace filter element and clean the (Fig 1-1)

recommendations:

reservoir breather cap, and hydraulic oil

reservoir at the recommended service intervals.

1. Store and handle hydraulic oil with utmost care

to prevent moisture and foreign matter from

CAUTION

entering the hydraulic system. All hydraulic oil

Keep the hydraulic system clean. A

handling equipment, such as a container, funnel,

contaminated hydraulic system is the

and hand pump, should be kept clean at all

major cause of hydraulic puma,

times and covered when not in use.

control valve, and packing wear or

2. Keep all fittings and connections tight to

failure. It is therefore advised that

eliminate oil leaks. However, do not tighten any

any oil that is added or replaced be

fittings excessively because damage or

filtered through a 10 micron filter. or

distortion will result.

finer, before entering the hydraulic

3. Before a component is removed from the

system.

hydraulic system, be sure to wash the

component and its surrounding area with

C. DAILY INSPECTION

cleaning solvent to prevent entrance of foreign

matter into the system. Cover all openings

Daily during operation, occasionally inspect the floor

immediately.

area where the lift truck was operating to check for oil

4. Whenever a fitting with a pipe thread is

leaks from the hydraulic system. Correct leaks as soon

removed, use a sealing compound on the

as they become evident.

outside of the threads before the fitting is

installed. Make certain all parts are thoroughly

Daily, check reservoir oil level. Oil should be up to the

cleaned before installation. Do not put sealant

full mark on dip-stick when mast is lowered and all

on first thread of fittings, it may contaminate

cylinders are retracted. Add specified oil if necessary.

system.

5. When a hose assembly is installed, make

D. 50 HOUR INSPECTION

certain it is not twisted when the fittings are

tightened. Always use two wrenches on swivel

1. Lift Cylinders

type fittings, one to hold the hose and the other

to tighten the fitting.

After each 50 hours of operation, inspect the

6. Keep nose clamps tight to prevent hose from

mast lift cylinder(s) for leaks; correct any that are

chafing and to avert leakage.

evident. Check lift cylinder hoses and fittings for

7. Oil leaks at the lift and tilt cylinders should be

leaks; correct if necessary.

corrected as soon as leakage becomes evident.

No adjustment can be made on the mast lift

cylinders. When leakage occurs, the seals must

be replaced.

2-85

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |