|

|||

|

|

|||

|

Page Title:

TOPIC 2. POWER SHIFT TRANSMISSION CHECK-OUT PROCEDURES |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 2. POWER SHIFT TRANSMISSION CHECK-OUT PROCEDURES

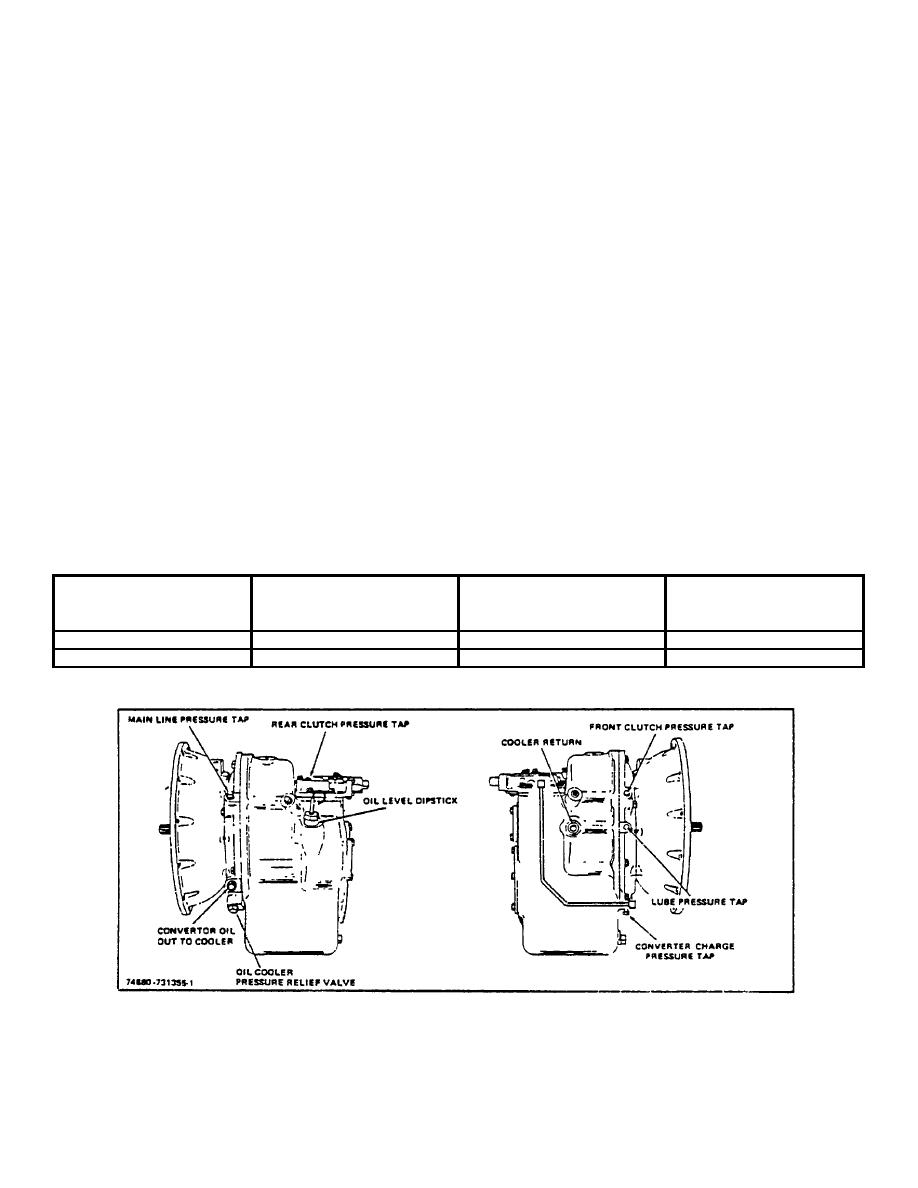

3. Mount a pressure gauge (0 300 p.s.i.) in the

NOTE

appropriate pressure tap port for each check.

The transmission oil level must be at

(See Figure 2-1).

the dipstick "FULL" level before

performing the following checks. All

4. Attach a tachometer to record the engine speed

the checks are made with the

(RPM). All checks are to be run at the specified

transmission oil temperature at 120

engine speed.

130 F.

Temperatures below 120

130 F will give a reading higher than

5. With the parking brake released, position the

specified for the individual check.

transmission in forward and accelerate engine to

the specified engine speed. Drive wheel brakes

A.

PUMP, TORQUE CONVERTER AND CLUTCH

must not drag.

PRESSURES

NOTE

1. Operate transmission until the transmission oil

Check

pressures at

both

engine

temperature rises to 120 130F. The required

speeds.

transmission oil temperature can be reached in

a short period of time by operating the

transmission with the torque converter stalled. A

6. Check pressure gauge reading. All readings

metal thermometer placed in the oil level dipstick

must be a steady value within the pressure

hole can be used to measure the oil

range indicated for each pressure check.

temperature.

Pressure Specifications for Power Shift (single speed)

2. Raise the front of the lift truck until both drive

Lift Trucks.

wheels clear the floor, then block into position.

Pump

Converter

Clutch

Pressure (p.s.i.)

Pressure (p.s.i.)

Pressure (p.s.i.)*

(see Figure 2-1)

(see Figure 2-1)

(see Figure 2-1)

Engine Speed (RPM)

600 RPM

40 min. - 110 max.

20 min. - 95 max.

35 min. - 105 max.

2000 RPM

115 min. - 140 max.

75 min. - 115 max.

95 min. - 130 max.

*Check clutch pressure with transmission in forward and reverse.

Figure 2-1. Pressure Tap Locations

M-171-1

2-53

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |