|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 3. WATER PUMP

A. DESCRIPTION

Liquid coolant is circulated through the engine and the

radiator by a centrifugal water pump. The pump is

enclosed in a sealed, cast metal housing and is flange

mounted to the front of the cylinder block. The pump

impeller is pressed on one end of the pump steel shaft

and the fan mounting hub is pressed on the other end.

The shaft is supported at the drive end by a sealed,

double row ball bearing, and is prevented from moving

endwise by a shoulder in the pump housing and a snap

ring on the outside.

The construction of the water pump is conducive to long

life with minimum attention if clean coolant is used in the

system. Water containing scale forming elements is

especially harmful to the pump parts due to corrosion.

The water pump requires no attention other than bearing

replacement when bearings show excessive looseness,

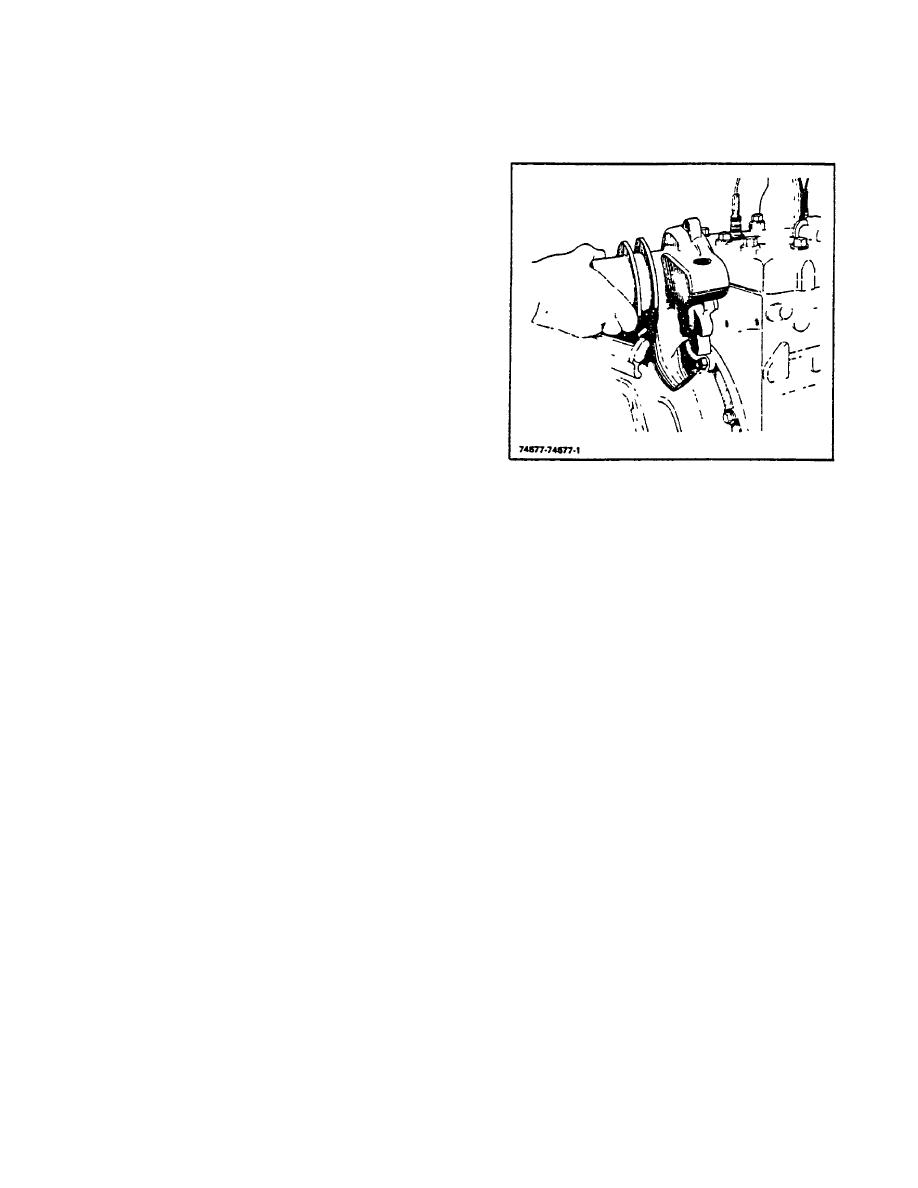

Figure 3-1. Removing Water Pump

or if a water leak develops, which shows a damaged or

badly worn seal that needs replacement.

2. Mount and secure

the

water

pump

with

mounting capscrews.

B. REMOVAL

3. Replace the coolant bypass hose and tighten

When it becomes necessary to remove the water pump

the clamps.

for service or replacement, the following removal

procedure is recommended (Figure 3-1)

CAUTION

Do not overtighten clamps as this

1. Open water drain (Figure 2-2).

could cause bypass hose to fracture

or split.

2. Disconnect by-pass hose and pump inlet hose.

4. Replace the coolant inlet line at the water pump,

3. Remove fan by taking out four capscrews.

and secure with clamp.

4. Loosen generator so that fan belt can be

5. Install the fan pulley, the fan blade and the

slacked off enough to slide over pulley.

mounting capscrews.

Tighten capscrews

securely.

5. Remove nuts and lockwashers holding the pump

body to the front of the block and remove the

6. Properly aign fan belt at fan drive pulley, fan

l

pump assembly.

pulley and alternator pulley.

NOTE

7. Force the alternator away from the engine with a

Refer to REPAIR MANUAL for WATER

long-handled screwdriver or pry bar, until the fan

PUMP DISASSEMBLY INSPECTION,

belt has approximately 1/2" to 3/4" deflection at

REPAIR and REASSEMBLY.

a point halfway between the fan pulley and the

alternator pulley, with about 10 lbs. applied

C. INSTALLATION

force. (Refer to Fan Belt Adjustment.) After

proper adjustment, secure alternator capscrews.

1. Clean the gasket mounting surfaces on water

pump flange and on cylinder block and install

8. Close water drains.

new gasket. Use approved sealing compound

as required.

9. Fill the cooling system to the recommended

capacity with proper coolant and replace radiator

pressure cap.

M-155-1

2-43

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |