|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 4. FUEL TANK

A. DESCRIPTION

2. Replace filler cap assembly.

The fuel tank is of steel construction with welded seams.

3. Loosen dr ain plug.

It includes a fuel level sender unit and a filler cap with

filter screen. The fuel tank requires little, if any service

4. Inspect for water contamination.

other than periodic cleansing of the fuel filter screen.

5. If contaminated, drain until water is emptied,

B. CLEANING AND INSPECTION

then close valve.

1. Remove fil!er cap assembly and check filter

screen for fouling. Clean if required, and dry

6. Connect outlet fuel line and fill tank to

with compressed air.

recommended capacity with proper octane fuel.

7. Check tank and fuel lines for leaks.

Repair if

necessary.

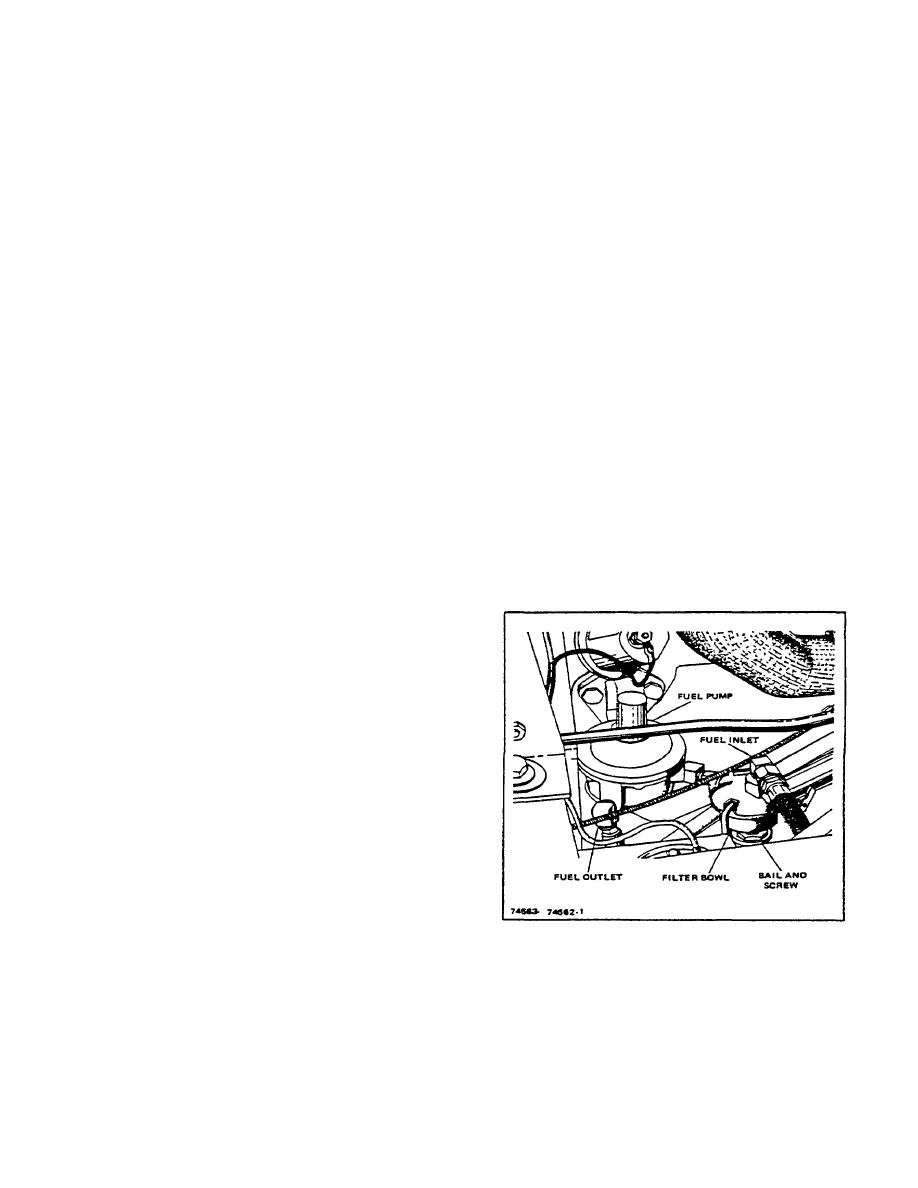

TOPIC 5. FUEL PUMP AND FUEL FILTER

A. DESCRIPTION

operating rocker arm.

Pressure should be

between 2-3/4 p.s.i. to 3 p.s.i. Pressure should

The fuel pump is a mechanical diaphragm type pump

not fall off rapidly.

with a strainer and sediment bowl.

The pump is

9. Install fuel pump as removed, ensuring new

mounted on the left side of the engine and is operated

mounting gasket is used.

by an eccentric cam on the engine camshaft.

10. Install and secure capscrews and lockwashers.

11. Connect inlet and outlet fuel lines. Do not over

Fuel from the tank enters the strainer-sediment bowl on

tighten connections.

the suction stroke of the pump and is forced to the

carburetor on the pressure stroke. Action is controlled

by two valves in the cover assembly.

B. REMOVAL AND INSPECTION

1. Disconnect fuel pump inlet and outlet lines.

2. Remove capscrews and lockwashers from fuel

pump mounting flange and remove pump.

3. Clean pump with solvent and dry with

compressed air.

4. Remove bowl and bowl gasket.

5. Remove strainer screen from top cover and

discard.

6. Install new strainer screen after ensuring that it

shows no damage or obstruction. New screen

must fit snugly around inner and outer edges.

7. Install new bowl gasket, swing bail assembly

into position over bowl, and tighten nut securely.

8. Test operation of pump valve by attaching

Figure 5-1. Pump Mounting

pressure

gauge

to

outlet

and

M-123-1

2-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |