|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

4. Refer to paragraph I for static ignition timing and

paragraph J for dynamic ignition timing.

5. If distributor is not going to be removed, install

contact set, if removed. Be certain that points

are in perfect alignment (Figure 5-3 and 5-4).

NOTE

Following data is required for proper

distributor to engine timing.

F. DISTRIBUTOR CHARACTERISTICS

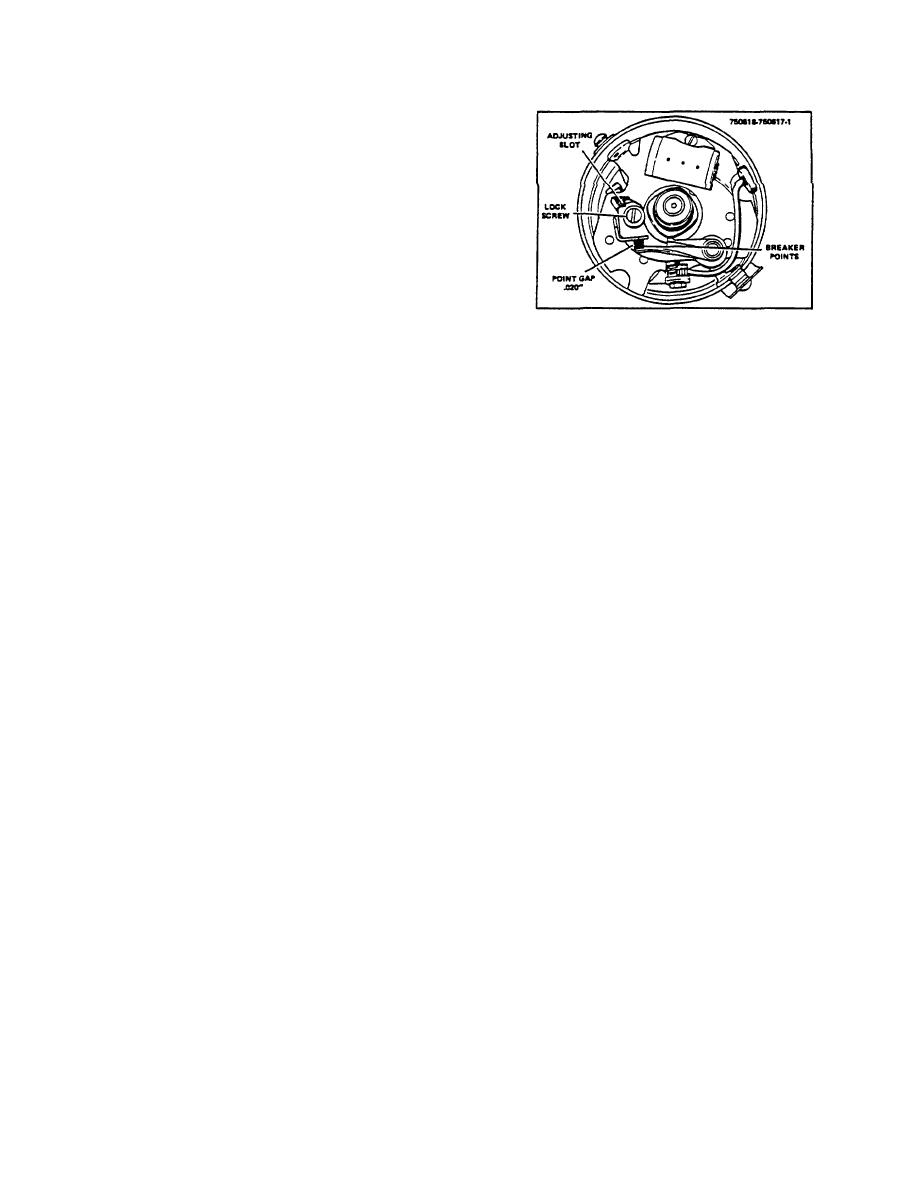

Figure 5-4. Adjusting Contact Gap (Type II Distributor)

Type II Distributor

Rotation ..................................C.C.W. (Viewing Rotor)

2. Slightly loosen the contact assembly locking

screw Figure 5-3 and 5-4).

Point Opening ..................................................020"

Cam Angle Range ......................................66 - 72

Start Advance (T.D.C.) ............................. 500 RPM

3. Insert a feeler gauge between the contact

points, insert a screwdriver in the adjusting slot

G. STATIC BREAKER POINT ADJUSTMENT

and turn clockwise or counterclockwise to

specified point gap. When properly adjusted a

slight drag will be felt when feeler gauge is slid

NOTE

between the points.

Refer to paragraph F for correct point

gaps and cam angles for the

4. Tighten locking screw and recheck gap for

distributor being serviced.

accuracy.

1. Nudge the starter switch until the breaker arm is

5. Replace dust seal, rotor and distributor cap.

resting on the high point of the cam. Attach a

remote starter switch between the battery

positive (+) terminal and the starter solenoid

H. DYNAMIC BREAKER POINT ADJUSTMENT

switch terminals. The truck starter switch can be

used but a remote switch is more convenient.

1. Disconnect high tension coil lead from distributor

and ground to engine-or frame.

2. Attach positive lead of dwell meter to the

negative terminal (-) of coil. Connect negative

dwell meter lead to ground.

3. Attach a remote starter switch between the

battery positive terminal (+) and the starter

solenoid terminal. The truck starter switch can

be used but the remote switch is more

convenient.

4. Remove distributor cap, rotor and dust seal.

Slightly loosen the contact assembly locking

screw and insert a screw driver in the adjusting

slot (Figure 5-3 or 5-4).

5. Use starter to crank the engine. Observe the

dwell meter. The meter will rise to a value and

then drop off each time the points open. Turn

the screwdriver in the adjusting slot until the

maximum value of the needle rise equals the

required dwell specification. See paragraph F.

M-104-1

2-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |