|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 2. VALVE ADJUSTMENT

A. DESCRIPTION

4. Place thumb over the spark plug opening and

slowly crank the engine until an outward

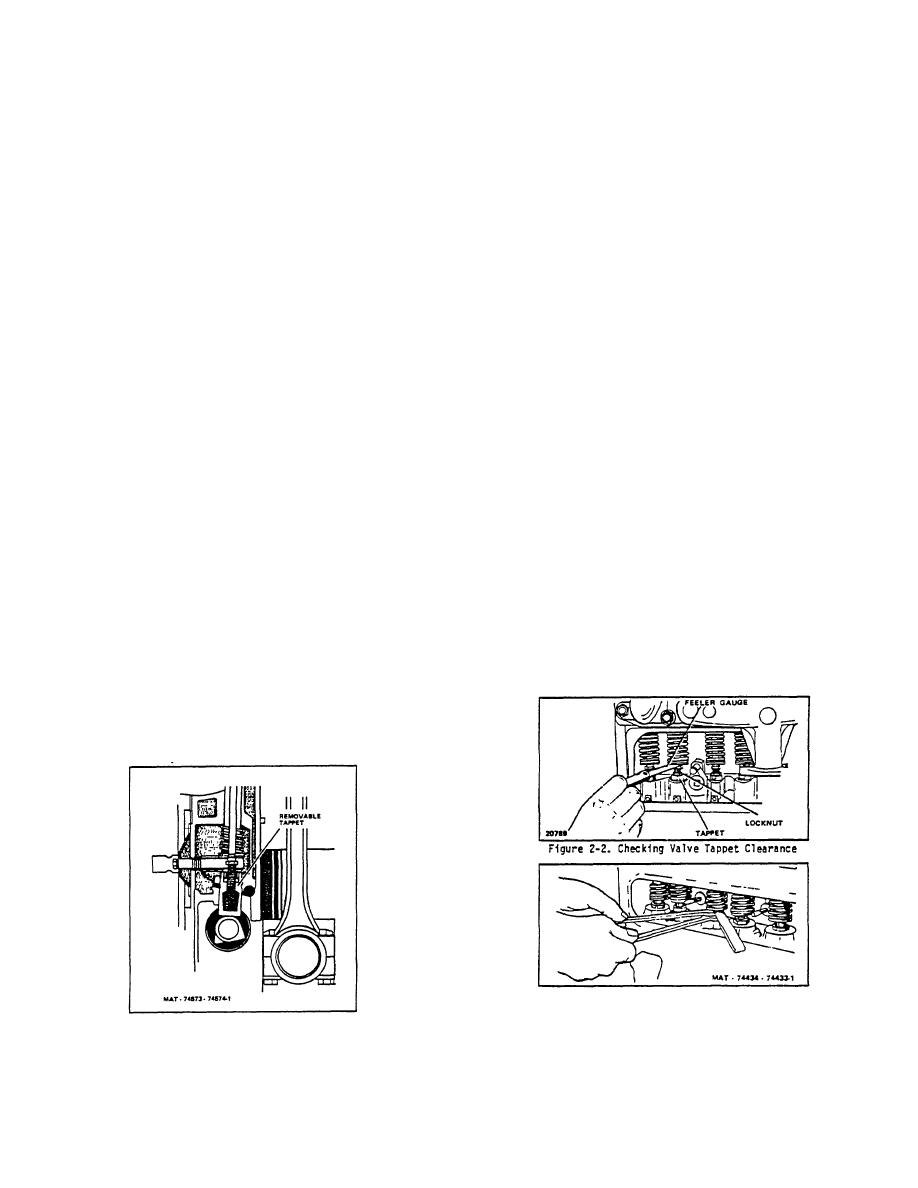

The valve tappets (Figure 2-1) are removable. These

pressure can be felt. Pressure indicates number

large, barrel shaped, pressure lubricated tappets are so

one piston is moving toward Top Dead Center of

designed that by removing the adjusting screw, the main

the compression stroke. Continue cranking until

body can be lifted out and replaced from above through

the timing mark on the flywheel is in center of

the valve chamber. This eliminates the costly service

the flywheel housing timing hole. Both valves

operation of dropping the oil pan and pulling the

are then closed on the compression stroke of

camshaft. Locking of the adjustment is both simple and

number one cylinder.

effective.

5. Use two thin wrenches when adjusting valve

Accurate valve tappet settings materially prolong engine

clearance. Use the lower wrench to hold the

life and aid performance.

in addition to impairing

tappet and the upper wrench to raise or lower

performance, excessive clearances are detrimental to

the tappet adjusting screw. When the valve lash

cams and tappets as well as to the rest of the valve

is properly adjusted, the appropriate feeler

mechanism.

When clearances are too low, the

gauge should pass between the tappet and its

possibility of burned valves increases.

corresponding valve stem with a slight drag

(Figures 2-2 and 2-3).

B. ADJUSTMENT

Check and adjust intake and exhaust tappets to

6. Crank the engine one-half revolution at a time

following clearances at running temperature:

and check the clearance of each valve; adjust if

necessary. Do this on each set of cylinder

Intake - .012"

valves in succession according to the firing order

Exhaust - .020"

of the engine, which is 1-3-4-2.

To adjust valve tappets proceed as follows:

7. Install new gasket and install valve tappet cover.

Check to see that the valve cover makes an oil-

1. Disconnect and ground the high tension coil wire

tight seal with the crankcase.

to prevent accidentally starting the engine.

8. Replace the spark plug, spark plug wire and coil

2. Remove the valve tappet cover from the left side

wire.

of the crankcase.

3. Remove the spark plug from number one

cylinder.

Figure 2-3. Adjusting Valve Tappet Clearance

Figure 2-1. Removable Valve Tappet

2-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |