|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

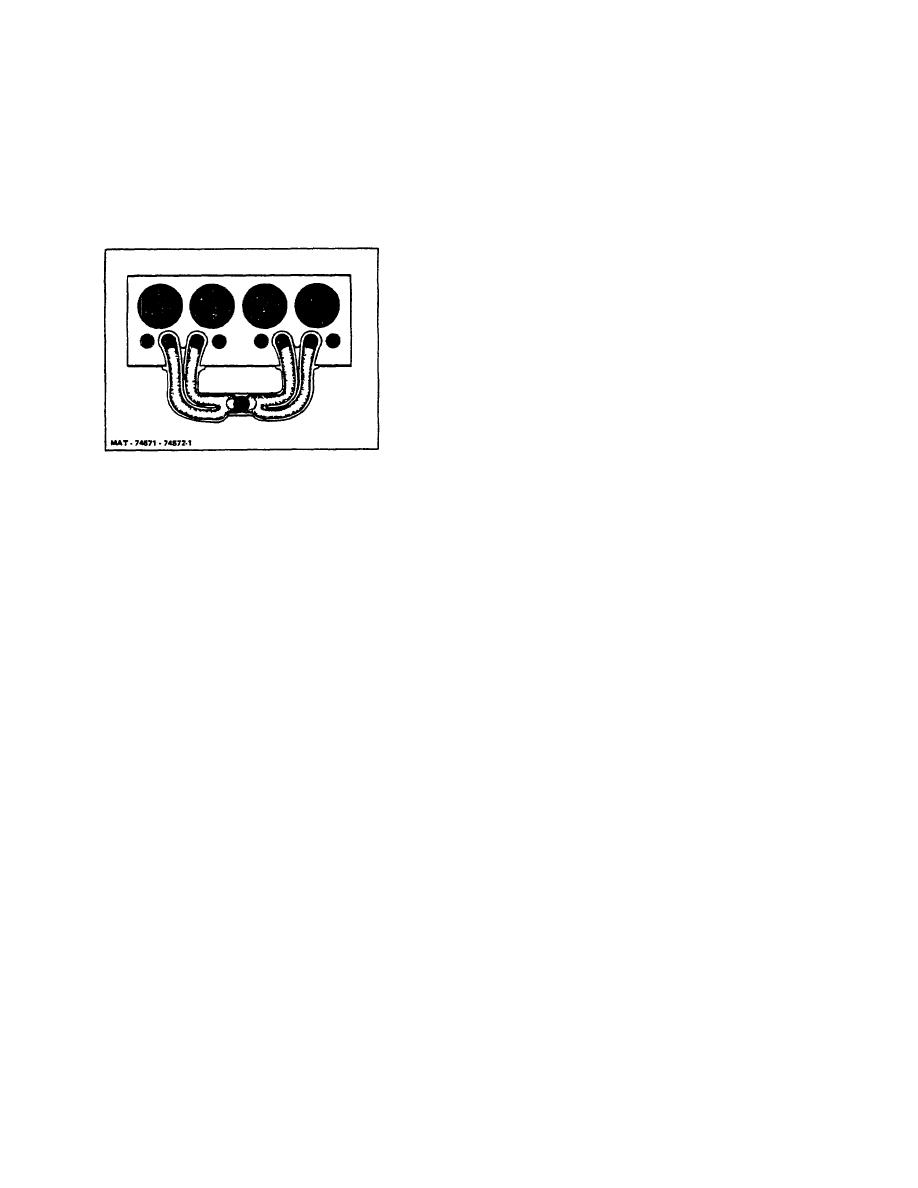

This is accomplished by casting the cylinder block with

8. Lubrication

individual intake valve passages for each cylinder and

Forced feed by oil pump driven directly

connecting these passages to an Intake manifold which

off camshaft, to all main, connecting

also has individualized passages for each cylinder.

rod and camshaft bearings as well as

tappets and timing gears.

This equal distribution results in maximum power,

smooth operation, easy starting and longer engine life.

9. Cooling

Coolant circulated by centrifugal pump

driven by 'V" belt from fan drive pulley.

Full pressure flow through engine at all times.

Engine capacity - 9 qts.

Engine and Radiator capacity - 9 qts.

10. Oil Pressure

Maximum - 30-40 p.s.i.

Minimum (Idling) - 7 p.s.i.

11. Oil Sump Capacity

Four quarts - add one-half quart extra when oil

filter is replaced. Throw-away cartridge type

filter.

Figure 1-2. Intake Manifold Individual Porting

12. Connecting Rods

Drilled for piston pin lubrication.

B. GENERAL SPECIFICATIONS

Bronze bushing at piston pin end.

1 Size and Piston Displacement

F163

Number of cylinders .....

4

13. Camshaft

Bore ............................

3.4375

Supported by 3 replaceable bearings.

Stroke .........................

4.375

Driven by helical gear from the crank-shaft.

Displacement (cu. in.) ..

162

Compression Ratio .......

7.4:1

14. Pistons

Aluminum with four piston rings -

2. Type

2 compression rings, 1 scraper ring and 1 oil

control ring.

Four stroke cycle - naturally aspirated.

15. Valves

3. Crankshaft Rotation

Located in cylinder block. Operated by valve

tappets directly from camshaft.

Clockwise facing fan end of engine.

Intake Valve Clearance - .012

Exhaust Valve Clearance - .020

4. Suspension

16. Crankshaft

Three point on rubber bushings.

Supported by 3 main replaceable bearings.

5. Ignition

17. Fan Drive Belt and "V" pulley on fan drive

adapter

Battery and distributor.

6. Firing Order

1-3-4-2. Number 1 cylinder at fan end of engine.

7. Spark Plugs

Standard metric 18 MM thread.

M-104-1

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |