| |

TM 10-3930-643-34

GENERAL SUPPORT PROPELLER AND PROPELLER SHAFTS MAINTENANCE.

16-3.

Rear Differential Carrier Assembly.

(Sheet 12 of 12)

ADJUSTMENT

NOTE

If gears were not replaced, use

backlash dimension recorded in

Step 1.

If gears were replaced,

use backlash dimension etched on

gear.

72.

73.

74.

75.

76.

77.

78.

79.

Adjust differential assembly

to

obtain correct backlash dimension by

backing off one adjustment ring and

advancing the

opposite

adjustment

ring by an equal amount.

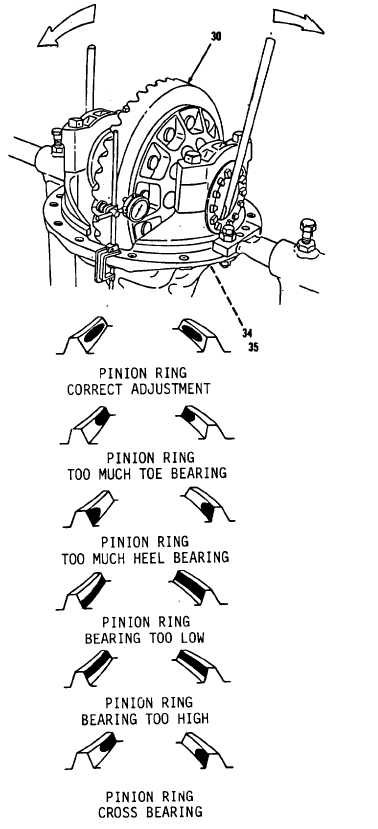

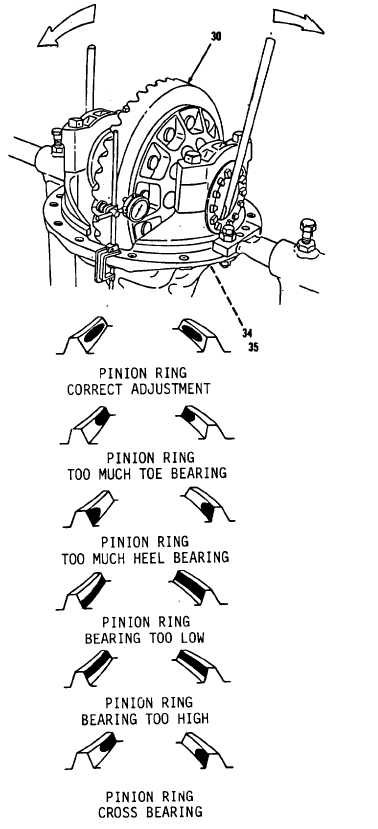

Measure clearance between gear

(30)

and screw (35).

Screw (35) on

vehicles S/N 2001 and above

only.

Clearance should be 0.010 to 0.015

inches.

Tighten nut (34) to 140 to 170 lb-ft.

Check gear tooth contact:

Coat

pinion gear teeth with gear mark.

Rotate pinion gear.

Check contact pattern on gear teeth.

if too much toe or heel bearing,

adjust cone center, refer to Step 61.

If bearing too too high or low,

adjust backlash, refer to Step 67.

If cross bearing, reject differential

assembly.

NOTE

Return M10A Forklift

equipment condition.

to original

END OF TASK

16-30

|