| |

TM 10-3930-643-34

GENERAL SUPPORT PROPELLER AND PROPELLER SHAFTS MAINTENANCE. (cont)

16-3.

Rear Differential Carrier Assembly. (Sheet 9 of 12)

ASSEMBLY (Cont)

48.

49.

50.

51.

52.

53.

54.

NOTE

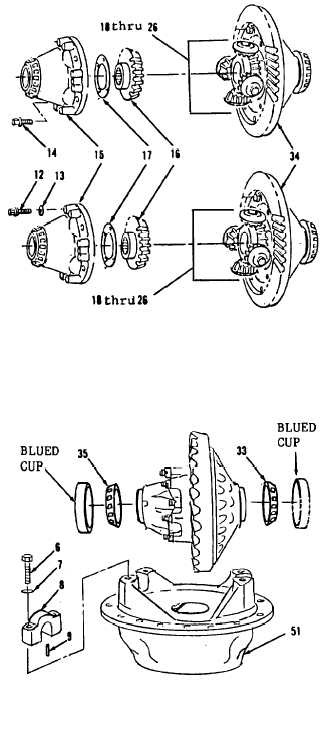

The following is a difference

between M10A Forklift models.

Be sure to aline identification marks

on cases (15 and 34).

Using a 1/2”

socket and socket wrench handle,

install case (15) with four equally

spaced bolts (14) on vehicles S/N 2001

to 2903 or case (15), 16 washers (13)

and bolts (12) on vehilces S/N 2000

and below and 2904 and above.

Check assembly for free rotation of

differential gears.

Install remaining bolts (14) and

washers (13) or bolts (12).

Tighten

bolts (13 or 12) to 105 to 135 lb-ft.

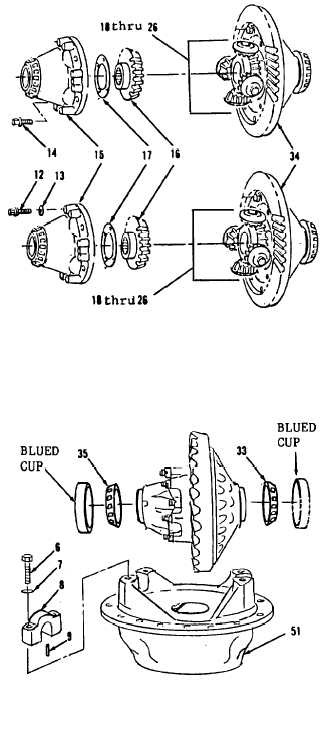

Install bearings (33 and 35) on

differential carrier and lubricate

with gear oil.

Using a 15/16” socket and torque

wrench, install blue cups, two pins

(9), bearing caps (8), four washers

(7) and bolts (6) to carrier (51).

Tighten bolts (6) to 160 to 190 lb-ft.

Identification marks on bearing caps

and carrier must be alined during

installation.

Check fit of cups in bearing cap

bores.

Cups must be a hand push fit.

If cups are too tight, bores must be

reworked with emery cloth until push

fit is obtained.

A blued cup should

be used as a gage to check fit,

Remove four bolts (6), washers (7),

two bearing caps (8), pins (9) and

blued cups.

Go to sheet 10

16-27

|