| |

TM 10-3930-643-34

GENERAL SUPPORT PROPELLER AND PROPELLER SHAFTS MAINTENANCE.

16-1.

Front Differential Carrier Assembly. (Sheet 8 of 13)

ASSEMBLY

NOTE

The following steps (41 thru 55)

is the assembly procedure for

differential carrier assembly for

vehicles S/N 2001 to 2903. The

assembly procedure for differential

carrier assembly for vehicles S/N

2000 and below and 2904 and above,

proceed to steps (56 thru 68).

When replacing parts, gears must

be replaced as a matched set.

Side gear thrust washers must be

replaced as a matched set.

41.

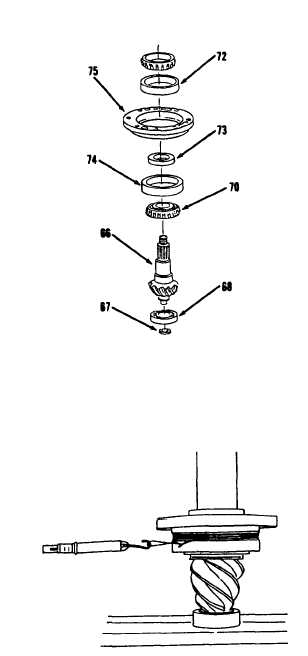

Install cup (74), spacer (73) and cup

(72) to cage (75).’

42.

Install cone (70) and bearing (68) to

gear (66).

43.

Install ring (67).

44.

Using arbor press, install gear (66)

in cage (75).

45.

Install cone (69).

46.

Rotate cage (75) to verify normal

bearing contact.

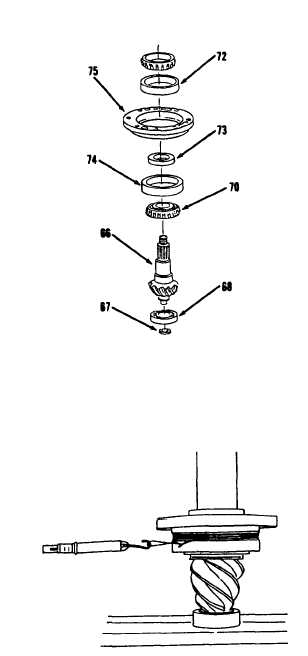

47.

Apply load of 6 tons with press as

shown.

48.

Using soft iron wire and scale

indicator, measure bearing preload

torque as shown. Bearing preload

torque should be 5 to 15 in-lb. Be

sure to measure rotating torque and

not starting torque.

Install thinner

spacer (73) to increase or thicker

spacer (73) to decrease preload as

required.

Go to sheet 9

16-9

|