| |

TM 10-3930-643-34

ENGINE, FUEL, EXHAUST AND COOLING

4-4.

Cylinder Head Assembly with

TROUBLESHOOTING AND MAINTENANCE. (cont)

Valves. (Sheet 10 of 18)

DISASSEMBLY/CLEANING/INSPECTION (cont)

32.

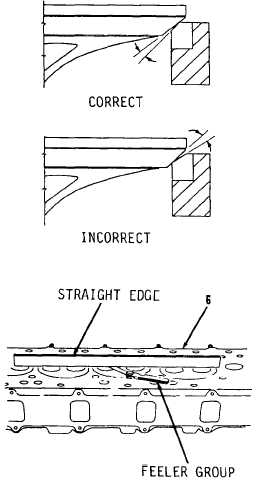

Recheck valve face contact with

Prussian blue if valve seats are

resurfaced.

33.

Place valves in proper guides and

position dial indicator against stem.

Raise valve approximately 0.5 inches.

Move valve against and away from dial

indicator parallel to cylinder

head

(6).

NOTE

If total indicator reading is more

than 0.004 inches, send

cylinder

head to General Support.

34.

Check valve seat for correct width,

as shown.

If necessary, correct

width by grinding top edge of

valve

seat with a stone of smaller

angle

(preferably 15 degrees) than valve

seat.

NOTE

If valve does not seat properly

after resurfacing

valve

seats,

cylinder head must be

sent to

General Support.

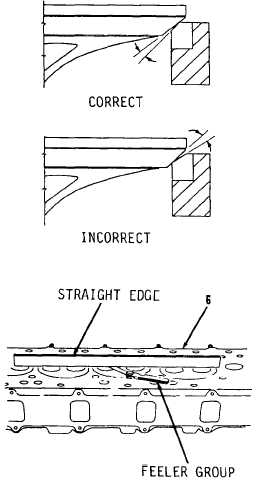

35.

Insert valves in cylinder head

(6).

Invert cylinder head (6).

Place

straight edge across valves.

Measure

distance from valves

to straight

edge.

Distance should be 0.000 to

0.014 inches. If necessary, grind

seat to different angle

to obtain

correct distance.

Go to sheet 11

4-38

|