| |

ENGINE, FUEL, EXHAUST AND COOLING

4-4.

Cylinder Head Assembly with

DISASSEMBLY/CLEANING/INSPECTION

TM 10-3930-643-34

TROUBLESHOOTING AND MAINTENANCE.

Valves. (Sheet 7 of 18)

17.

18.

19.

20.

Attach fitting, pressure gage and

hose to thermostat

housing plate.

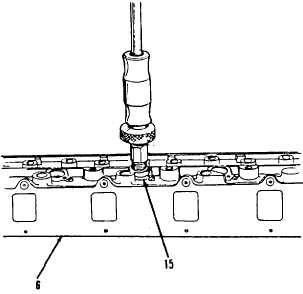

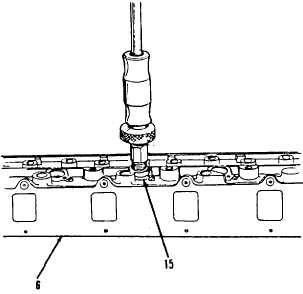

Run hot water into cylinder head (6)

at 25 psi.

Observe cylinder head (6) for leakage

at injection nozzle sleeve

flanges,

upper deck, lower deck, ports and

seat insert areas.

Inspect lower deck for flatness.

Use

a straight edge long enough to

span

both length and width of cylinder

head (6).

Follow checking pattern

shown.

Insert feeler gage under each

point shown.

NOTE

Cylinder head must be replaced if

0.003 inch feeler gage can be

inserted under

straight

edge

across length or width.

Sudden

changes in

contour

such as

scratches, gouges, etc., must not

exceed 0.002 inches in depth.

Remove and discard six sleeves

(15)

with slide hammer and nozzle

sleeve

puller adapter.

Go to sheet 8

4-35

|