| |

GENERAL SUPPORT

13-8.

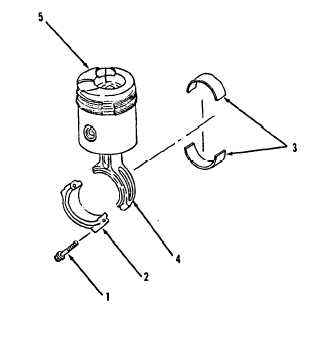

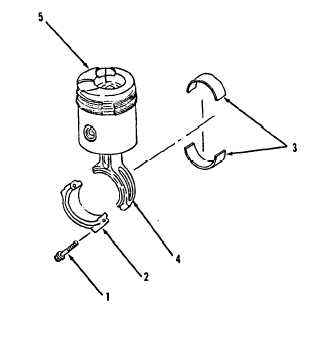

Pistons,

ASSEMBLY

TM 10-3930-643-34

ENGINE, FUEL, EXHAUST AND COOLING MAINTENANCE.

Connecting Rods and Connecting Rod Bearings. (Sheet 11 of 12)

39.

Avoid striking cylinder sleeve

with connecting

rod

when

installing pistons. Failure to

follow this procedure will result

in damage to the cylinder sleeve.

Using piston ring compressor, insert

through the top of the cylinder head

to compress ring as you install

piston (5).

The numbers on the rod

must face away from

the camshaft.

The valve depression on the top of

piston (5) must

face toward the

camshaft.

INSTALLATION

40.

Coat two bearing halves (3) with moly

lube.

Install bearing half (3) on

connecting

rod (4) in

lower

crankcase.

41.

Using a

wood punch,

tap

down

connecting rod (4) and piston

(5)

onto

crankshaft.

Make

sure

connecting rod (4) does

not

nick,

scratch or damage crankshaft.

42. Position bearing half (3) and cap (2)

on connecting rod (4).

NOTE

If bolts (1) are being replaced,

it will be necessary to repeat

step 43, three times.

New bolts

need to be loosened and re-

torqued three times.

This only

applies to new bolts.

43.

Using a 5/8” socket and torque

wrench, install two bolts

(1).

Tighten to 60 lb-ft, then 130 lb-ft.

Turn crankshaft and check tightening.

Go to sheet 12

13-59

|