| |

TM 10-3930-643-34

GENERAL SUPPORT ENGINE, FUEL, EXHAUST AND COOLING MAINTENANCE. (cont)

13-8.

Pistons, Connecting Rods and Connecting Rod Bearings. (Sheet 8 of 12)

CLEANING/INSPECTION (cont)

20•

21.

22.

23.

24.

25.

26.

27.

28.

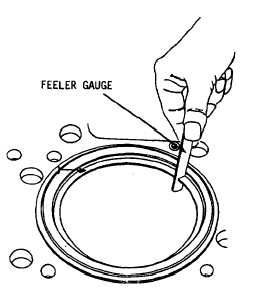

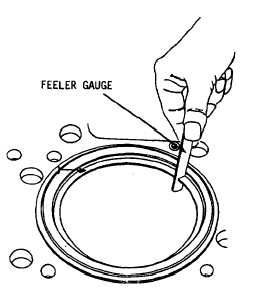

Push new rings (6 and 7) down into

cylinder sleeve with the top of a

piston positioning ring squarely in

the sleeve.

Using a feeler gage, measure ring

gap.

Replace ring if gap is too

wide.

File ring to

specification.

Ring (6) gap should be between 0.010

and 0.029 inches.

Ring (7) gap

should be between 0.020 and

0.033

inches for narrow gap

and between

0.065 and 0.078 inches for wide gap.

Inspect pin (10) and replace if worn,

etched or corroded.

Inspect two bolts (1) for nicks or

thread damage, replace if necessary.

NOTE

Rods have a special rolled thread.

Do no retap rods.

Lubricate thread of two bolts

(1)

with SAE 30 engine oil.

Screw two

bolts (1) into connecting rod (4)

face by hand.

If two bolts (1) does

not screw into connecting

rod (4)

freely, replace connecting rod (4).

Using a

micrometer,

measure

and

record the three inside diameters of

each rod at points “A”, “B” and “C”.

Inspect two bearing halves (3) for

deep scratches, wear or burned areas.

Insert two bearing halves (3) into

connecting rod (4) and cap (2).

Check crank pin diameter of

crankshaft, refer to paragraph 13-4.

Go to sheet 9

13-56

|