| |

TM 10-3930-643-34

FRAME AND TOWING ATTACHMENTS MAINTENANCE.

10-2.

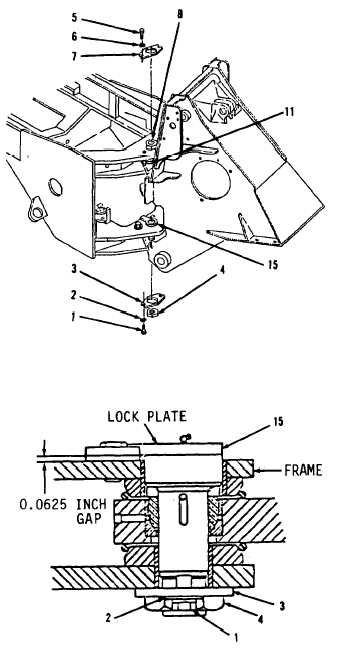

Frame Hinge Pin and Frame Assembly. (Sheet 4 of 13)

ADJUSTMENT

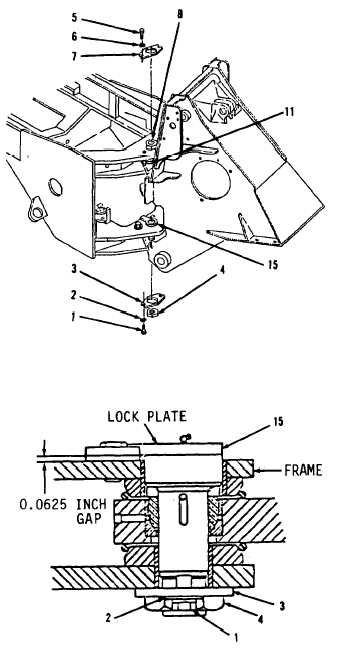

16.

Using a feeler gage, measure

clearance between lock plates and

frame ears.

Shafts (11 and 15) and

their lock plates must not make

contact with frame ears.

A minimum

of 0.0625 inch must exist between

lock plate and frame.

If clearance

is incorrect, refer to step 29 for

shim installation.

17.

Using a 15/16" socket and socket

wrench handle, install retainer plate

(7), two washers (6) and bolts (5).

Retainer plate (7) can be turned over

if it does not aline with nut (8).

If retainer plate (7) still does not

aline with nut (8), loosen or tighten

nut (8).

Do not turn nut more than

30 degrees.

18.

Using a 3-1/16" socket, socket wrench

handle and torque wrench, install nut

(4) and tighten to 190 lb-ft. Tap

head of shaft (15) solidly with hammer

while tightening nut (4) to seat shaft

(15).

19.

Loosen nut (4).

20.

Tighten nut (4) by hand with retainer

plate (3).

21.

Raise forklift to maximum height and

lower in jerky increments. This will

help to seat mating components.

22.

Recheck vertical frame movement with

dial indicator, refer to step 6. If

dial indicator reading still exceeds

0.010 inch, determine if movement is

all up and down.

If movement is

anything but vertical, replacement of

worn parts is necessary.

If measure

exceeds 0.010 inch and is all up and

down, repeat steps 18 and 19.

Increase tightening of nut (4) to 220

lb-ft.

Go to sheet 5

10-9

|