| |

TM 10-3930-643-34

STEERING TROUBLESHOOTING AND MAINTENANCE.

9-2.

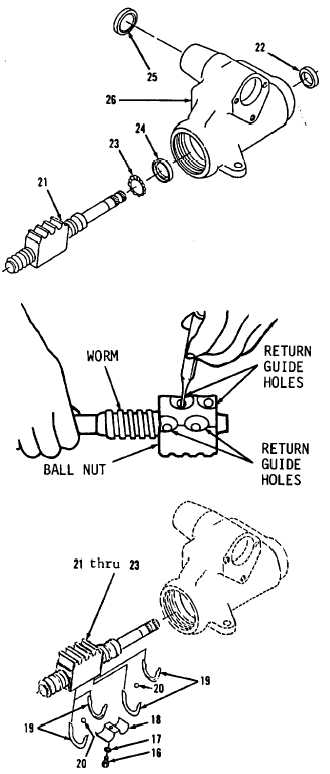

Steering Gear Assembly. (Sheet 5 of

CLEANING/INSPECTION (cont)

15.

Inspect 54 balls (20) for flat spots

or wear.

Balls (20) should be

same

size within 0.0001 inch.

16.

Inspect all other parts.

Refer to

paragraph 2-9.

ASSEMBLY

NOTE

All parts must be clean and free

of abrasive dirt.

All moving

parts must be lubricated with

multi-purpose gear grease.

17.

Using a wooden dowel and hammer,

install new seals (25 and 24),

bearing (23) and ring (22).

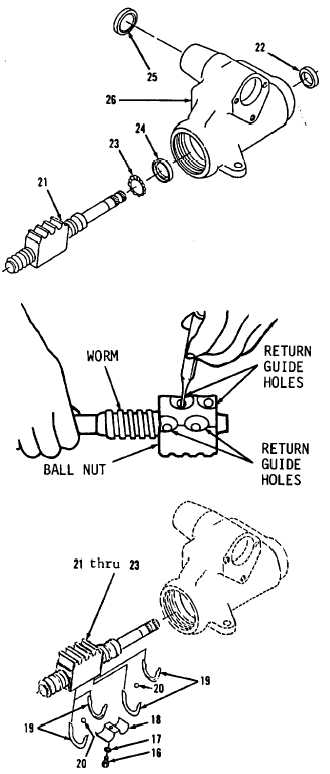

18.

Position ballnut and worm assembly

(21) with return guide holes facing

up.

19.

Aline grooves in ballnut and worm

assembly (21).

20,

Using pliers,

insert 27 balls (20)

into any return guide hole.

21.

Slowly rotate worm away from guide

holes while inserting balls (20).

22.

Continue inserting balls (20) until

circuit is filled from the bottom of

one hole to the bottom of the

other

or until stopped by reaching end of

worm.

(cont)

8)

Go to sheet 6

9-10

|