| |

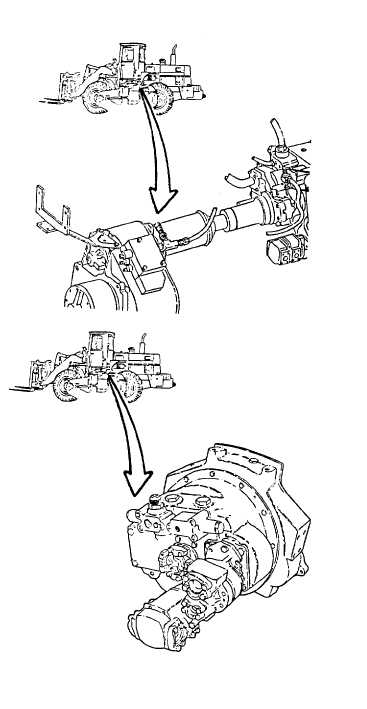

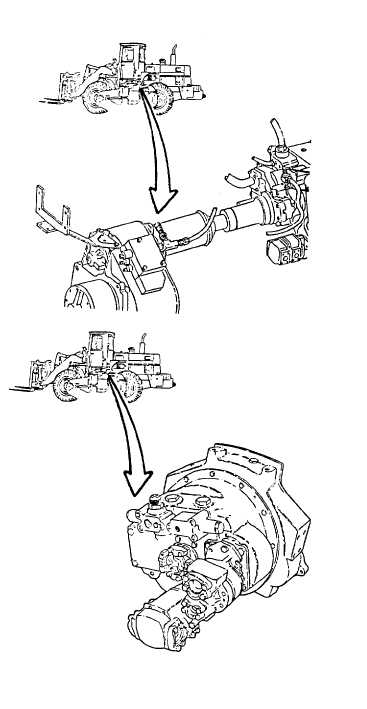

TM 10-3930-643-34

TRANSMISSION TROUBLESHOOTING AND MAINTENANCE. (cont)

6-3.

Torque Converter. (Sheet 2 of 9)

TESTING

1.

2.

3.

4.

5.

6.

Using an 11/16” open end wrench,

install pressure

gage at clutch

pressure tap in transmission and

torque converter.

Using a 3/4” open end wrench, install

pressure gage at torque converter

charge pressure tap.

Operate engine.

NOTE

Engine,

torque

converter

and

transmission should be at

normal

operating temperature.

Accelerate engine to 1000 to 1200 rpm

with transmission in neutral for not

longer than three minutes. Do not

exceed 1200 rpm.

Using a pressure gage, check clutch

pressure.

Clutch pressure should be

270 to 310 psi.

If a minimum clutch

pressure of 160 psi is not reached

within 30 seconds after

engine is

operating at low idle (675 to

700

rpm), shut down

engine. Do not

perform stall check test.

Using a pressure gage, check torque

converter charge pressure.

Charge

pressure should be 25 to 35 psi.

Go to sheet 3

6-12

|