| |

TM 10-3930-643-34

ENGINE, FUEL, EXHAUST AND COOLING TROUBLESHOOTING AND MAINTENANCE.

4-9.

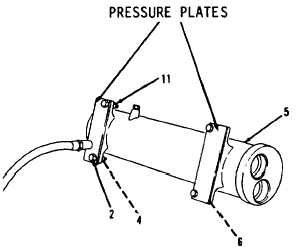

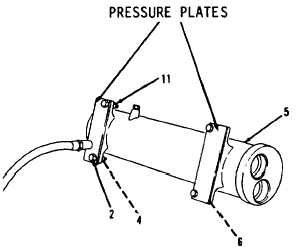

Oil Cooler. (Sheet 4 of 5)

TESTING

8.

9.

10.

11.

12.

NOTE

Plugs must be installed in oil

cooler for testing.

Install two new seals (6) and two

pressure plates to inlet and outlet

flange of oil cooler (5), refer to

Appendix D, Part D-5 for fabrication

of pressure plates.

Using a 9/16” socket and socket

wrench handle, install four

washers

(4), bolts (2) and nuts (11).

Attach air hose and immerse oil

cooler (5) in water. Water should be

at 120 degrees F.

COMPRESSED AIR HAZARD

Compressed air used for cleaning

purposes will not exceed 30 psi.

Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc.).

Using an air hose, apply 15 psi

pressure. No moving or growing

bubbles should be visible for about

one minute.

If moving or growing

bubbles are present after one minute,

replace cooler.

Remove oil cooler (5) from water and

disconnect air hose.

Go to sheet 5

4-71

|