| |

TM 10-3930-643-20

ENGINE, FUEL , EXHAUST AND COOLING TROUBLESHOOTING AND MAINTENANCE .

4-33.

Drive Belts. (Sheet 5 of 5)

ADJUSTMENT

23.

24.

25.

U s i n g d i a l i n d i c a t i n g s c a l e a nd

straight edge, as shown, apply 25

l b - f t a t p o i n t A f o r a l t e r n a t or

drive belts (14) at rear of engine.

Pleasure deflection.

Deflection

should be I-1/32 inches for a newly

installed alternator

d r i v e b e l t

( 1 4 ).

Recheck deflection after 1

h o u r o f o p e r a t i o n.

Deflection

should be 1-3/32 inches.

Maximum

a l l o w a b l e d e f l e c t i o n is

1-3/16

inches.

T O r e t e n s i o n a l t e r n a t or

d r i v e b e l t ( 1 4 ) , l o o s e n a l t e r n a t or

mounting bolt (8) and mounting

nut

(9) and reposition alternator (10)

as required.

U s i n g d i a l i n d i c a t i n g s c a l e a nd

s t r a i g h t e d g e , a p p l y 2 5 l b - f t at

point B of air compressor drive belt

( 1 3 ).

Measure

d e f l e c t i o n .

Inflection should be l-1/16 inches

for newly installed air compressor

drive belt (13).

Recheck deflection

after

1

hour

of

operation.

D e f l e c t i o n s h o u l d b e 3 / 4 i n c h.

Maximum allowable deflection is

1-3/16 inches.

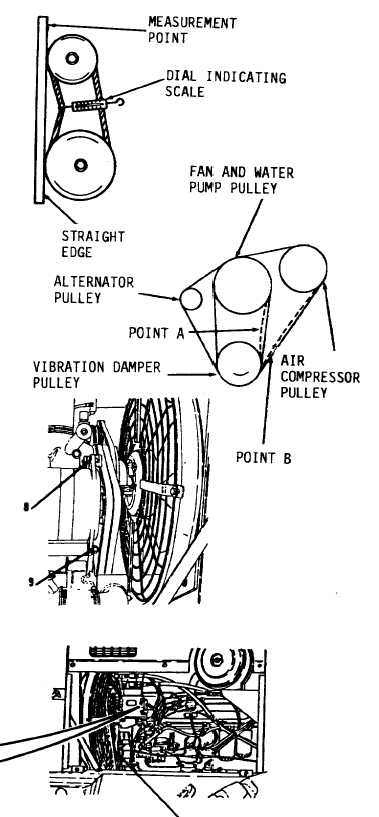

T o r e t e n s i o n a ir

compressor drive belt (13), loosen

air compressor mounting stud

nuts

(15) and turn adjusting bolt (16)

clockwise to tighten air compressor

drive belt (13) and counterclockwise

to loosen,

as required.

Return M10A Forklift to original

equipment condition.

NOTE

END OF TASK

4-145/(4-146 blank)

|