| |

T M 1 0 - 3 9 3 0 - 6 4 3 10

Operator/Crew Preventive Maintenance Checks and Services

NOTE :

Within designated interval, these checks are to be

performed in the order listed.

B - Before

D - During

A

-

A f t er

W

-

W e e k l y

Item

N0.

I n t e v a l

B D A W

1

2

—

—

—

Item To Be Inspected

Equipment Is NOT

Procedure: Check and have repaired,

filled

READY/AVAILABLE

IF:

or adjusted as needed.

IMPORTANT:

PERFORM WEEKLY (W) AS WELL AS

BEFORE (B) OPERATIONS PMCS IF:

1.

You are the assigned operator and have

not operated the vehicle since the last

weekly PMCS.

2.

You are operating the vehicle for the

first time.

EXTERIOR OF FORKLIFT

a. Check for oil, brake fluid, fuel,

Class III leaks.

coolant and hydraulic, leaks or appearance

of leaks.

b.

Visually check Rollover Protective

Obvious damage,

Structure (ROPS) or cab for obvious

bends and cracks

damage, bends and cracks in weldment.

in weldment.

c.

Visually check forks, carriages,

Forks, carriage, or

and side shifter frame for cracked, bent

side shifter frame

or broken frame members.

are cracked, bent

or broken.

d.

Visually check wiring harness and

Wiring is frayed,

connections for frayed or broken wires.

broken.

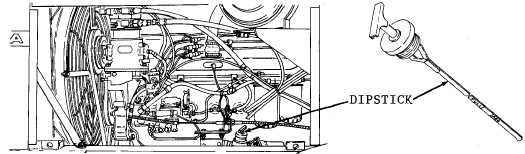

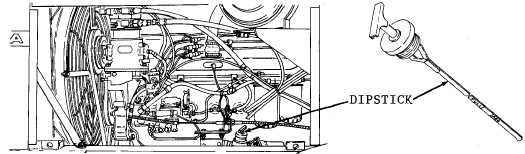

ENGINE LEVEL

Check level on dipstick. Maintain oil

level to between ADD and FULL mark.

I

T A 3 2 7 9 19

2-17

|