| |

TM 10-3920-638-24&P

4 - 4 . T R A N S M I S S I O N M A I N T E N A N C E ( c o n t )

f. Reverse and Second Clutch Assembly (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION

5

Reverse and second

Inspect

Inspect teeth for wear, pits, cracks, nicks

shaft drum and

and scores. Inspect shaft and quills to make

plug assembly (18)

certain they are not sprung, bent or have

twisted splines, and that shafts are true. In-

spect overall for wear, cracks, distortion

and damage. If any of these conditions are

observed, replace reverse and second shaft

drum and plug assembly

6

Inspect each disc for wear, cracks, damage

and breaks. If any of these conditions

are observed, replace disc

7

Inspect for cracks, distortion, broken con-

dition, wear and evidence of permanent

set. If any of these conditions are ob-

served, replace spring

8

Inspect rollers and cages for wear, chips,

nicks and damage. [f any of these con-

ditions are observed, replace bearing.

Dip bearings in clean light oil and wrap

in clean lintless cloth or paper

9

All other parts

Inspect for wear, damage, cracks and dis-

tortion. If any of these conditions are

REASSEMBLY

observed, replace part

10

Inner clutch discs (13, 24), Inspect

outer clutch discs (14,

25)

Piston return springs

Inspect

(17), piston spring

(28)

Bearings (4, 8, 10)

Inspect

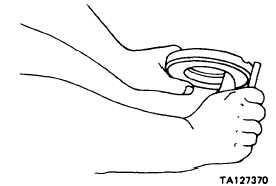

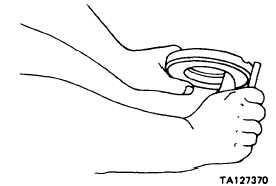

Clutch

a. Outer clutch

Inspect

Install and

size

Lubricate oil seal with OE10 (refer to

piston (29)

piston seal (30)

current lubrication order). To size

seal, rotate clutch piston while

holding a round object against new

seal as shown. Rotate clutch piston

until seal is flush with outer

diameter of clutch piston

4-200

Change 1

|