| |

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

f. Pistons and Connecting Rods (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION (cont)

11

Connecting rod (3)

Inspect

Check for cracks, damage, wear, scoring,

and connecting rod

and pitting. If any of these conditions

cap (2)

observed, replace as an assembly

12

Connecting

a. Piston pin

Measure

Use bore gage, then measure bore gage

rod (3)

bushing (10)

inside diameter

with micrometer. Replace if measure-

ment is greater than 1.2510 inches

NOTE

Perform following step only if piston pin bushing requires replace-

ment.

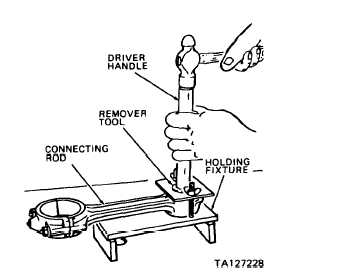

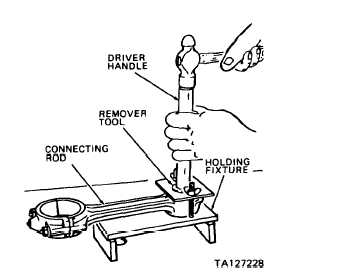

b. Piston pin

Replace

Use 1-5/16 inches diameter sleeve or rod

bushing (10)

to press from connecting rod. Align oil

hole in replacement bushing with oil hole

in connecting rod before pressing bushing

in. Press until flush with rod. Ream

bushing to 1.2502-1.2504 inches if new

piston pin is to be installed; if old piston

pin is used, ream bushing 0.0004 to

0.0015 inch larger than piston pin

diameter

4-47

|