| |

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

e. Flywheel and Flywheel Housing (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSTALLATION (cont)

CAUTION

In following step don’t use torch to preheat ring gear.

WARNING

Wear asbestos gloves to prevent burning your hands when handl-

ing heated parts.

16

Flywheel

a. Flywheel (9)

Position

On work bench

assembly

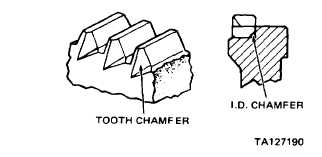

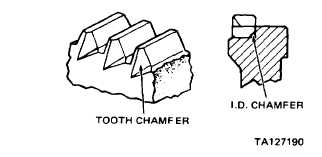

b. Ring gear (8)

Preheat and

Use oven or hot oil; heat to 400-450

install

degrees F. Install on flywheel (9) with

chamfer side of gear teeth outward and

larger inside diameter chamfer toward fly-

wheel

c. Flywheel

Position

On crankshaft; same position of timing

assembly (7)

mark as noted during disassembly

d. Four cap screws (5)

Install

Tighten to 65-70 pounds foot torque

and washers (6)

17

Flywheel

a. Dust cover (4)

Position

housing (17),

b. Three cap screws (1)

Install

front

lock washers (2) and

washers (3)

4-40

|