| |

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

d. Crankshaft and Main Bearings (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSTALLATION (cont)

17

cont)

18

19

20

Connecting

rod bearing

cap (2)

Crankshaft

(8)

Cylinder

block

e. Plasti gage

Bearing liner

Connecting rod

journals

a. Four connecting

rod bearing

caps (2)

b. Eight connecting

rod nuts (1)

c. Front main bearing

cap (4)

d. Oil pump

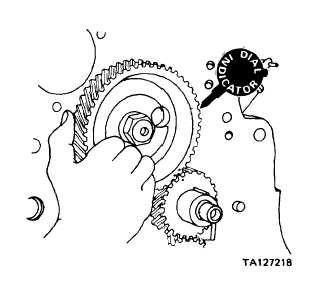

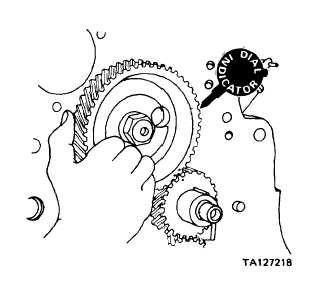

e. Crankshaft gear

(9) and camshaft

gear

Measure

Lubricate

Lubricate

Position

Install

Position

Install

Check back-

lash

Flattened plasti gage located on bearing

cap liner or crankshaft journal. Measure

widest point. Oil clearance shall be

0.0010 to 0.0040 inch. If necessary,

install undersize bearing liners to obtain

this dimension

Located in bore of bearing caps; use

No. 30 oil

Use No. 30 oil

Tighten to 45-50 pounds foot torque

Para 4-2i

Place dial indicator on camshaft gear. Back

lash between gear (9) and camshaft gear

shall be 0.0002 to 0.006 inch. If back-

lash exceeds 0.006 inch, replace gears

NOTE

Excessive backlash may also be caused by

worn camshaft bushings.

4-36

|