| |

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

a. Cylinder Block Assembly (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

REASSEMBLY (cont)

b. Measure sleeve

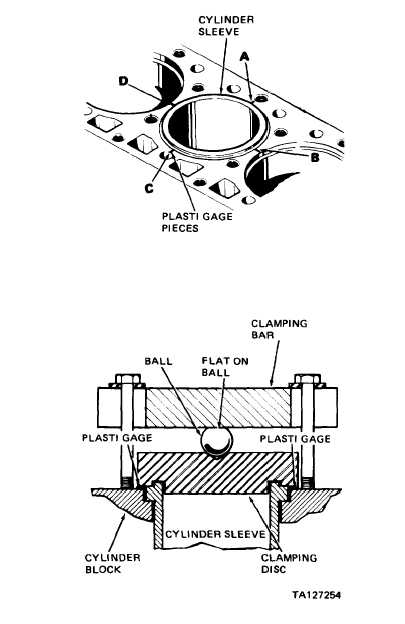

Position plasti gage at four points shown.

(cont)

protrusion

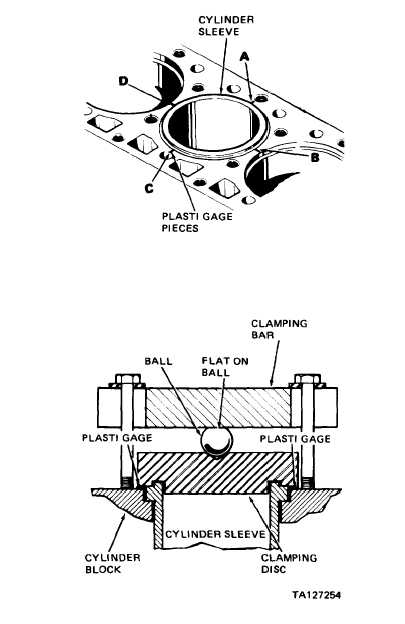

Plasti gage must not protrude onto sleeve

flange. Install clamping disc tool care-

fully over sleeve as shown. Install 1 inch

ball and clamping bar. Tighten hold dew]

bolts evenly to 50 pounds foot torque.

Then, remove clamping bolts, bar and

ball. Carefully remove clamping disc so

as not to disturb plasti gage. Flattened

plasti gage will be on clamping disc or

block. Measure plasti gage. If sleeve pro-

trusion varies more than 0.005 inch

around circumference, replace that sleeve

and recheck

4-8

|