| |

TM 10-3930-638-24&P

3-29. HYDRAULIC LIFT SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. UNABLE TO TILT LOAD (ALL OTHER FUNCTIONS NORMAL) (cont)

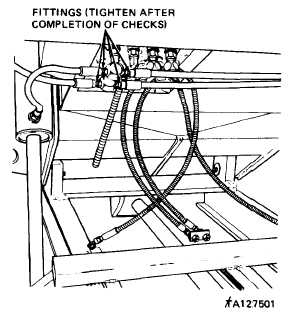

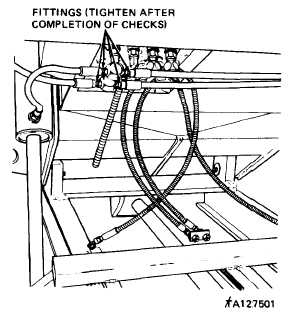

Step 4. Crack (loosen) fittings shown at side.

Start engine and operate at idle speed.

Place LIFT control lever in RAISE posi-

tion until forks are three feet from ground.

Place TILT control lever in FWD position

and check if hydraulic oil flows from

loosened fittings; place TILT control lever

in REAR position and check if hydraulic

oil flows from loosened fittings,

a. If hydraulic oil does not flow from

loosened fittings, replace control valve

(para 3-30a).

b. If hydraulic oil flows from fittings,

proceed to step 5 (tighten fittings

loosened above).

Step 5. Start engine and operate at idle speed.

Place TILT control lever in FWD position

until mast assembly is tilted fully forward.

Turn engine off and operate control levers

several times to relieve hydraulic pressure.

Disconnect and cap hose fitting connected

to rod end of tilt cylinder assembly.

CAUTION

Don’t place TILT control lever in REAR position in following

steps. Hydraulic oil will flow out of disconnected hose fitting.

Start engine and operate at idle speed.

Place TILT control lever in FWD position and hold while an assistant checks for hydraulic oil leakage

at tilt cylinder assembly port from which fitting was disconnected.

Repeat the above for other tilt cylinder assembly.

a. Remove tilt cylinder assembly and repair piston assembly (para 3-30b) if hydraulic oil leakage

is observed.

b. If hydraulic oil leakage is not observed, remove and repair control valve (para 3-30a).

3-200

|