| |

TM 10-3930-638-24&P

12-12. COOLING SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

ENGINE OVERHEATS (cont)

Step 6. Check thermostat (para 2-17d).

Replace thermostat (para 2-17d).

2.

ENGINE DOES NOT REACH OPERATING TEMPERATURE

Check thermostat (para 2-17d).

Replace thermostat (para 2-17d).

3. COOLING SYSTEM NOT PRESSURIZED

NOTE

With engine at normal operating temperature, run engine at high

speed for two minutes and return to idle speed. Carefully cover

radiator cap with a cloth and rotate counterclockwise to first

detent. A hissing noise from cap and filler neck indicates that

system is pressurized.

Step 1.

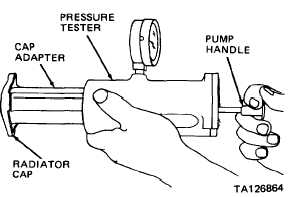

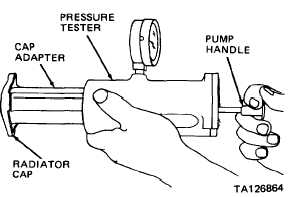

Allow engine to cool and remove radiator

cap (para 2-17a).

Rinse radiator cap with clear water and in-

stall on cap adapter and pressure tester as

shown.

NOTE

It may be necessary to reinstall radiator cap

several times to ensure tight seal.

Operate pressure tester pump and observe

meter reading at its highest point.

Cap release pressure should be 6 to 9 pounds,

and should remain steady for at least 30 seconds.

a. If radiator cap pressure is 6 to 9 pounds, and remains steady for at least 30 seconds before

dropping, proceed to step 2 below.

b. If radiator cap pressure is not 6 to 9 pounds, or if pressure drops rapidly, replace radiator cap

Step 2.

Disconnect cap adapter from pressure tester.

Attach pressure tester to radiator filler neck, with locking ears in line with entrance notches of filler

neck.

Press down on tester and rotate clockwise until locking ears are stopped by stop lugs on radiator filler

neck.

Clamp radiator inlet and outlet hoses, or block hose flanges.

Operate pressure tester pump until meter indicates 9 pounds pressure, and observe meter.

2-26

|