| |

TM 10-3930-638-24&P

3-10. STARTER AND SOLENOID TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Armature

Current

Probable

Inspection

Speed

Draw

cause

Data

High

Low

High

Zero

Zero

Open field circuit.

Open armature coils.

Poor brush contact.

Zero

Grounded terminals or fields.

Frozen bearings.

Low

High internal resistance.

Low

Excessive friction.

Shorted armature.

Grounded field coils or

armature.

High

High

Shorted field coils.

Check internal connections and field coils for open

condition.

Inspect commutator for badly burned bars after

disassembly.

Check for broken brush springs, worn brushes,

and high insulation between commutator bars.

Disconnect field coil ground connections and check

for grounded condition.

Rotate armature by prying pinion with a

screwdriver.

Check for poor connections, defective leads, and

dirty commutator.

Check for tight, dirty, or worn bearings, bent

armature shaft or loose pole shoes allowing

armature to drag.

Check armature in a growler after disassembly.

Disconnect field coil ground connections and check

for grounded condition.

Replace field coils and repeat bench test.

2. STARTER FAILS TO CRANK

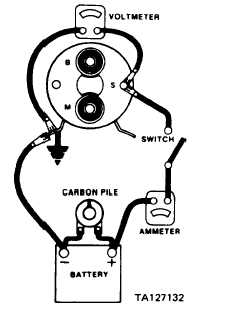

Step 1. Disconnect and tape field coil lead at solenoid M terminal.

Connect solenoid terminals to test set-up as shown.

Close switch, adjust carbon pile for 9 Vdc indication on

voltmeter, and note ammeter reading.

a.

b.

If ammeter indicates 6.5 to 7.0 amperes, proceed

to step 2.

If ammeter does not indicate 6.5 to 7.0 amperes,

replace solenoid switch (para 3-13).

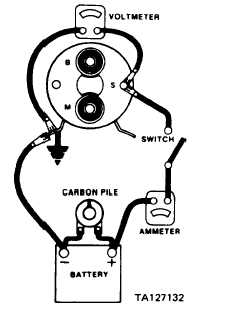

Step 2. Reconnect solenoid terminals to pull-in winding test

set-up as shown on following page.

CAUTION

To prevent overheating solenoid, do not close switch for more

than 15 seconds at a time.

Close the switch and adjust carbon pile for 20 Vdc indication on voltmeter.

Note ammeter reading and open switch.

3-91

|