| |

TM 10-3930-638-24&P

3-6. FUEL SYSTEM MAINTENANCE (cont)

c. Fuel Injection Pump (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION (cont)

9

Thrust plunger (10)

Inspect

Replace if cracked, bent or excessively worn

10

Cover plate (8)

Inspect

Replace if cracked, distorted, or damaged

11

Injection pump flange and Inspect

Use fine stone or crocus cloth to remove

mating surface on timing

any nicks or burrs from mating surfaces

gear housing

INSTALLATION

12

Drive shaft (15)

NOTE

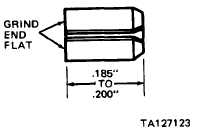

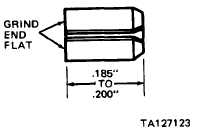

Replacement drive shaft (15) includes roll pin (16). Perform

steps a and b below only if roll pin (16) requires replacement.

a. Roll pin (16)

Fabricate

Use 10988 P/N 138-275 roll pin and grind

flat on one end to the overall length shown

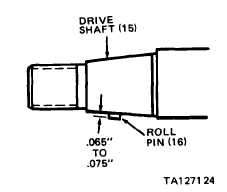

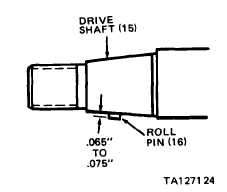

b. Roll pin (16)

Install

Press into drive shaft (15), chamfered end

first, to the dimension shown below

3-82

|