| |

TM 10-3930-638-24&P

3-3. ENGINE TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

7. ENGINE COMPRESSION TEST

Remove fuel injectors, and clean fuel injector

bores in cylinder head (para 3-6b).

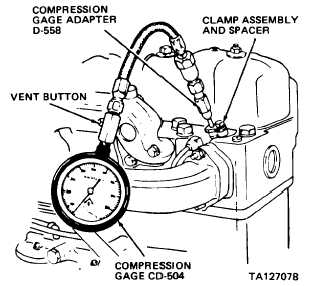

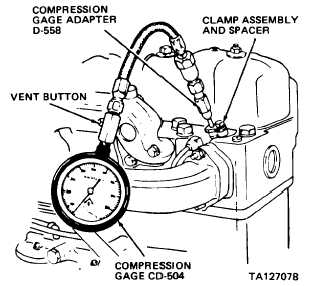

Install D-558 compression gage adapter

(FSCM 05083 P/N 70-314) in fuel injector

bore at No. 4 cylinder, and secure with clamp

assembly and spacer as shown.

Connect compression gage (FSCM 10988

P/N CD-504) to adapter, crank engine with

starter, and record gage reading.

Depress vent button to relieve gage pressure

and repeat test.

NOTE

Engine cranking speed must be approximately 200 RPM for

reliable test results. If necessary, charge batteries to maintain

proper cranking speed.

Disconnect compression gage and adapter from No. 4 cylinder and repeat above test at remaining

three cylinders.

The gage reading for any one cylinder at a given altitude above sea level must not be less than the

minimum listed in the chart below.

In addition, the difference between gage readings for the highest and lowest cylinders should not exceed

25 PSIG.

CYLINDER COMPRESSION TEST CHART

Minimum Compression

Altitude Above

Pressure at 200 RPM

Sea Level

(PSIG)

(Feet)

400

0

384

1,000

360

2,500

320

5,000

280

7,500

240

10,000

3 - 5

|