| |

TM 10-3930-638-24&P

2-3. SERVICING NEW EQUIPMENT

(10) Check that all drain plugs are securely tight-

(cont)

ened.

b. Service Check.

a. Removal of Protective Compounds. Remove

preservative compounds from metal surfaces with

cleaning solvent P-D-680. Check and ensure that all

fill opening are clear.

b. Cleaning. Clean all dust and dirt from seat,

instrument panel, wiring, engine, and radiator

c. Lubrication. Lubricate vehicle in accordance

with LO 10-3930-638-12.

2-4. INITIAL CHECKOUT AND

ADJUSTMENT

a. Inspection.

(1) Inspect equipment for damage incurred dur-

ing shipment. If equipment has been dqamaged, report

the damage on DD Form 6, Packaging Improvement Re-

port (refer to DA PAM 700-3 for instructions on prepara-

tion of DD Form 6).

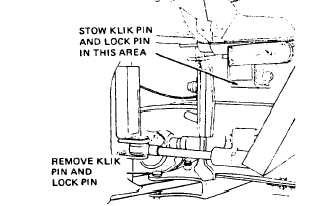

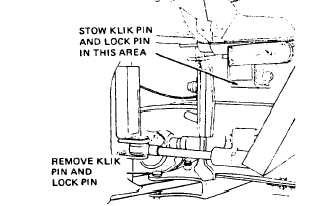

(1) Remove shipping klik pin and shipping lock

pin from holes in front and rear chassis and stow in stor-

age area as shown below.

(2) Perform before operation PMCS (refer to the

separate Operator’s Manual, TM 10-3930-638-10).

2-5. MOVEMENT TO NEW SITE

(2) Check equipment against packing slip to see if

shipment is complete. Report all discrepancies in accor-

dance with instructions of TM 38-750.

(3) Check to see whether equipment has been

modified.

WARNING

If NBC exposure is suspected, all air filter

media should be handled by personnel wear-

ing protective equipment. Consult your unit

NBC Officer or NBC NCO for appropriate

handling or disposal procedures.

(4) Check air cleaner for damage.

(5) Cheek gages and instruments on instrument

panel for broken glass or other damage.

(6) Check control levers for bent or broken condi-

tion.

(7)) Check engine accessories f’or loose connec-

tions and insecure mounting.

(8) Check wiring for loose connections, damaged

insulation. and broken wires.

(9) Check fittings, lines, and hoses for cracks,

loose connections, and broken or missing parts.

2-2 Change 5

a. Driving. The vehicle may he moved under its

own power without any special preparation or may be

transported on a suitable truck and flat bed trailer. If

transported on on a flat bed trailer:

WARNING

Be sure ramp is securely fastened to flat bed

trailer to prevent personnel injury and

damage to equipment.

(1) Place ramps between flat bed trailer and

ground.

NOTE

Ramps shall not provide a grade of more than 40

percent.

(2) Drive vehicle up ramps and position on flat

bed trailer. Turn engine off and apply parking brake.

(3) Install blocking at front, rear, and sides of

vehicle.

(4) Install tiedowns at front and rear axles (refer

to plate 20, paragraph 1–1 2).

b. Towing. Vehicle is towed rearward using tow

bar and chains located on rear. special procedures shall

be performed prior to towing operation. Refer to

preparation for movement, Operator’s Manual, TM

10-3930-638-10, for these procedures.

|